"We turn robots into geckos"

Judith Hillen

At the zoo, everyone has surely watched a gecko miraculously walk vertically up the glass pane of its terrarium. The startup INNOCISE, which is part of the 5-HT network, transfers this effect from nature to industry: Inspired by the fine microstructures on the feet of geckos, INNOCISE develops innovative adhesive systems with which a wide variety of objects can be gripped and moved precisely, without leaving any residue and saving energy. In an interview with 5-HT, CEO and Co-Founder Dr. Marc Schöneich, explains the advantages INNOCISE offers compared to classic gripping systems and how it can be used, for example, to advance laboratory automation in pharmaceutical companies.

INNOCISE Team

INNOCISE TeamWhat is the idea of INNOCISE?

INNOCISE is a spin-off of the Leibniz Institute for New Materials in Saarbrücken, Germany, working on bioinspired adhesion mechanisms. We have developed a gripping system to turn robots into geckos. Our technology builds on decades of research at the Leibniz Institute for New Materials, where, under the direction of Prof. Eduard Arzt, we investigated which biological adhesion mechanisms we can adopt from nature. It turned out that the model of the gecko is particularly interesting for industrial applications. One and a half years ago, INNOCISE was therefore founded to bring this effect to market with scalable products.

How does the gecko's example help develop better gripping systems?

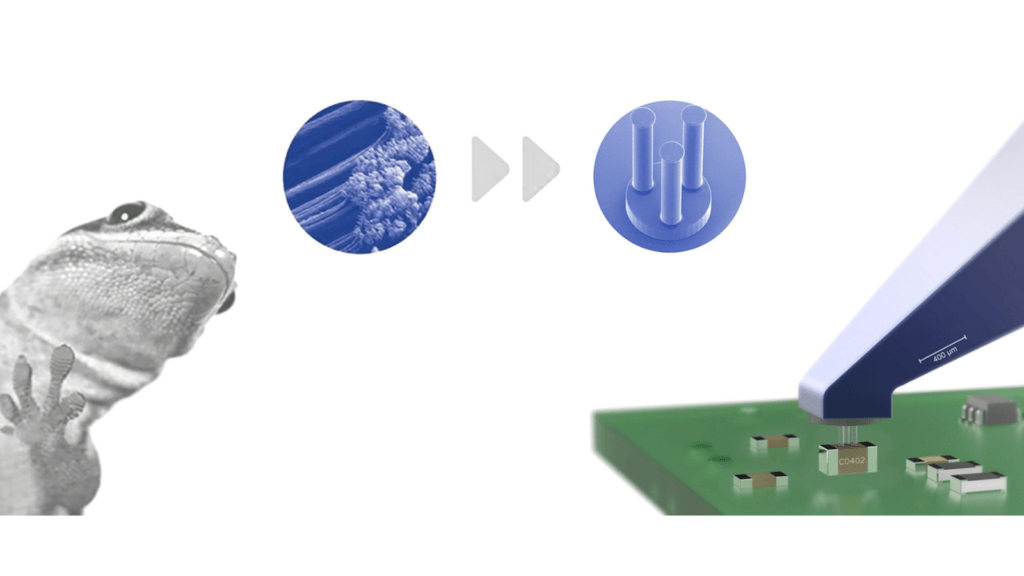

We know from research why the gecko sticks so well to surfaces: It's because of the Van der Waals forces that develop between the tiny hairs on the gecko's feet and the contact surface. If our skin were structured like that of a gecko, we could lift a table without any problem just by placing our hand on the wooden surface. Based on the principle of the gecko, we at INNOCISE are now developing innovative gripping systems for various surfaces and handling applications. However, we do not build the robot or the gripper, but only the fingertip of the gripper. This has the advantage that we can adapt to any existing system at the customer's site and that an integration of our Gecomer® technology can be realized quickly and cost-effectively. We use different microstructures and materials for the different operating conditions of our customers.

Based on the model of finely structured adhesive elements of the gecko's foot, highly precise and switchable adhesive structures were developed for use in the handling of components.

Based on the model of finely structured adhesive elements of the gecko's foot, highly precise and switchable adhesive structures were developed for use in the handling of components.What can be gripped with the gripping systems from INNOCISE?

When asked this question, the first thing I always like to explain is what we can't grab: Our goal is not to lift an oily steel sheet from A to B - there are other solutions for that. What we can grip very well, however, are smooth, sensitive surfaces where high precision and residue-free gripping are required. In terms of size, we are very flexible - we can grip extremely small objects such as micro LEDs or glass fibers, for example, as well as 15 m² glass sheets or car body components.

What are the different applications for INNOCISE systems?

We have three areas of application: First, we offer gripping systems for collaborative robotics, and second, we equip robot cells and linear axes with our system. In this macroscopic area, we have already realized many exciting applications, for example with strategic customers in the pharmaceutical and packaging industries. For this, we are also working with SCHUNK, the market and innovation leader in the field of gripping systems, which markets a product with our technology under the name SCHUNK ADHESO. The third area, which we currently see as the growth segment for our technology, is microhandling: for example, for electronic components in the single-digit micrometer range, there are hardly any alternatives to our technology, because classic suction systems cannot generate sufficient vacuum at this size, and two-finger grippers do not manage to grip such small components at all. That's why this area is very exciting for us.

To what extent are INNOCISE's adhesive systems also relevant for the pharmaceutical industry?

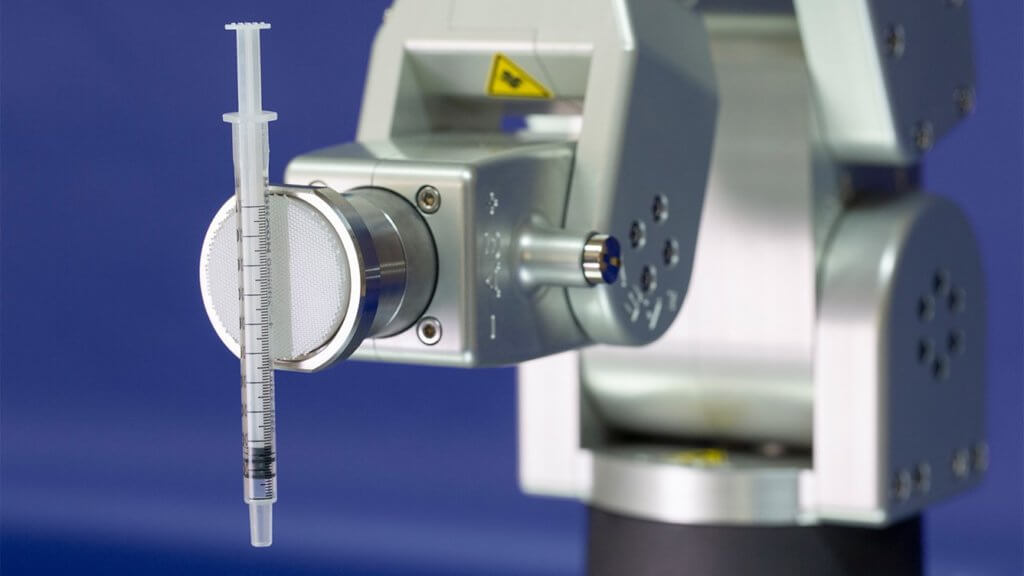

For us, the pharmaceutical industry is the number one sector in which we see great potential for our solution. Our gripping systems are particularly relevant in the field of laboratory automation, because their precise and residue-free gripping makes them especially well suited for use under cleanroom and laboratory conditions. This involves, for example, sterile packaging, syringes or containers that should only be gripped at very specific points and must not be damaged or contaminated in the process. For pharmaceutical companies interested in our solution, we would be happy to conduct a feasibility study free of charge.

Application in the pharmaceutical industry: Residue-free gripping under cleanroom and laboratory conditions

Application in the pharmaceutical industry: Residue-free gripping under cleanroom and laboratory conditionsWhat are the main advantages of INNOCISE compared to conventional gripping systems?

A major advantage is the sensitive gripping, which does not leave any residue and does not damage the object. A particularly important point is also that our systems do not require any external energy. This means that our customers do not have to set up cables, batteries and, above all, a compressed air supply. This not only allows them to save significant costs, but also reduces their emissions and makes their production more sustainable. In addition, our systems can operate under reduced atmospheres, making them suitable for vacuum applications in modern production facilities. In addition, the systems are very flexible - not only in terms of component size, but also in terms of straightforward integration with various robots or linear axes. The process of gripping and releasing is very fast with our products. Unlike vacuum or two-finger grippers, we don't have to wait for a vacuum to build up or for the fingers to grip, because the Van der Waals forces are there immediately. In manufacturing, we also make sure from the outset that the plastics used are recyclable, so our products are as green as possible.

What are the next goals for INNOCISE?

With the SCHUNK ADHESO product now commercially available, we want to get off to a good start in the market, gain visibility, address additional customers and thereby set new standards in the industry. In addition, we are currently intensively engaged in the field of microhandling, where we are constantly developing our solutions and looking for additional customers in our target markets.

How can 5-HT support you as you move forward?

We look forward to exchanging ideas with other young companies or other players from the 5-HT network. If we decide to do another capital increase to accelerate our growth, it would certainly also be interesting to establish contacts with corporate VCs from the chemical or pharmaceutical industry for this purpose. In addition, we are always open to people who are interested in our technology and would like to learn more about it - for example, as part of an internship or as part of the INNOCISE team.

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!