"We make the use of AI in production acceptable"

Judith Hillen

In order to better analyze and control production processes, the Dresden startup Symate uses artificial intelligence: The software system Detact collects production and quality data from various sources and interprets them according to the users' needs. In an interview with 5-HT, David Haferkorn, Director of Product Management and Business Development at Symate, explains the benefits of using artificial intelligence in production - and how companies in the pharmaceutical and chemical industries can profit from it.

How can your software Detact improve production processes?

Detact offers a unique infrastructure for the use of artificial intelligence in heterogeneous process chains. Our software collects technology data and digitizes it, automatically merges the data, performs user-related analyses as well as interpretations, and then visualizes the results in an engineer-friendly form. This works via drivers that automatically address a large number of heterogeneous data sources and synchronize their information - from SPS systems and peripheral devices to MES and CAQ systems and a wide variety of database and file types. After analyzing the data using AI methods, the results are visualized in various apps for engineers and machine operators in a user-specific manner.

What sections can be optimized with your software?

On the one hand, we enable effective troubleshooting, i.e. we provide a transparent overview of the process situation, facilitate the detection of anomalies and implement root cause analysis. On the other hand, Detact enables users to optimize their processes in a targeted manner. The system gives them clear recommendations for action to increase the overall equipment effectiveness (OEE). In addition, Detact enables the active use of the system as an assistance system such as for adaptive quality control, quality prediction or as an AI-supported startup assistant.

What are the main fields of application in the pharmaceutical and chemical industry?

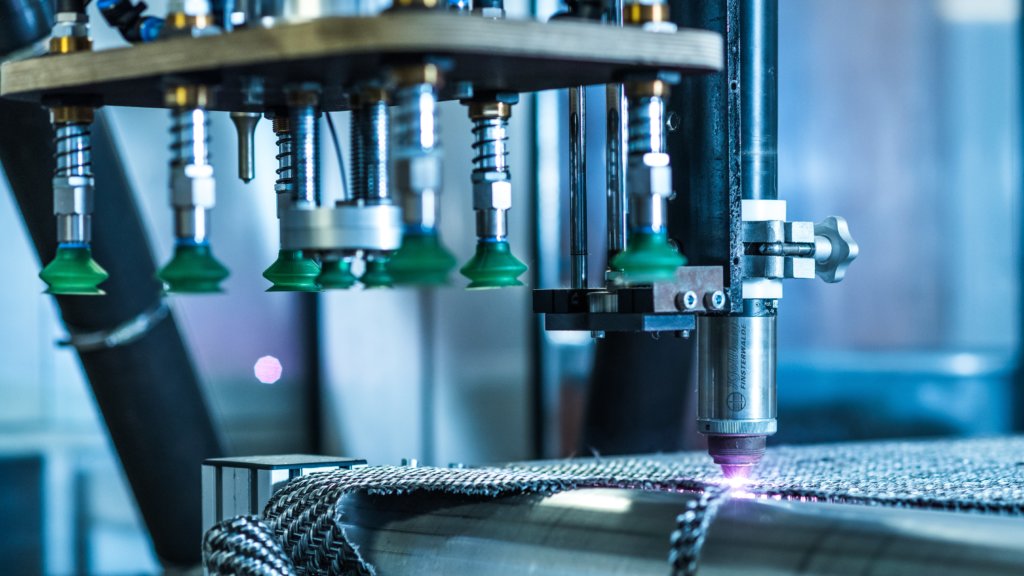

In principle all types of production processes can be optimized with Detact. The main focus of our work is plastics processing - a field which is of great importance for medical technology, but also for process engineering in the chemical sector, and which results in interesting applications. For example, we are able to determine correlations between the material and various processing parameters and, on this basis, derive recommendations for setting parameters. In addition, we are also intensively engaged in recycling, i.e. the reuse of already produced materials. In addition, we can generate an overall parameter data set from globally collected, highly complex information, predict properties of the finished material and provide recommendations for the optimum processing window.

How does Detact distinguish itself from other existing systems?

We differ from ordinary IoT (Internet of Things) platforms because we do not simply provide data and standard applications for analysis. We go one step further! We work user-oriented - that means, we provide the right information at the right time for specific everyday tasks according to the needs of the individual user in order to initiate self-diagnostic, partly self-regulating processes on this basis. Our system does not require any special conditions. Rather, we focus strongly on the individual customer and his individual requirements. Therefore we are able to integrate very heterogeneous data sources. Small and medium-sized companies, which make up the majority of the German economy, benefit from this, as they generally have limited resources. With our data-driven approach, we ensure that they remain in control of the situation at all times and can act as efficiently as possible on the market with the help of AI-supported decisions.

Why was Symate founded and Detact developed?

Our startup was developed from a special research project at the TU Dresden. The main objective was to research new material compounds. In order to be able to better map the interactions within the processes, the idea for a data-based approach was born and thus the first rudimentary preliminary stage of Detact. With this software we were able to analyze which process parameters affect which quality properties and how. This was the hour of birth for Symate GmbH, which was founded in 2012 by Dr. Gunnar Dietz, Dr. Martin Juhrisch, Dr. Jens Weller and Dr. Hajo Wiemer. I came into contact with Symate GmbH myself in 2017 through a project in plastics processing that I supervised. Our cooperation gradually developed from the need for a solution for data analysis across process chains. Finally, I joined the team and, as a domain expert, took care of product management and business development.

What is the current status of developments?

Detact has continuously developed since its spin-off from the TU Dresden. In 2019 we took Detact to a new level and introduced version 2.0. This version is Big-Data capable, and our customers work with a completely new, intuitive user interface. In addition, the company itself has grown significantly. We now have almost 20 employees in the fields of software development, mathematics and engineering. Until today, we can do without investors, because we finance ourselves exclusively through our customer projects. This drives us and ensures that we develop the solutions our customers really need. Together with these companies, we develop pilot projects in workshops, which we then implement on the basis of a jointly developed roadmap.

What are your next steps?

Through continuous work with the individual tasks of our customers we are constantly improving our processes and meanwhile we also focus on international projects. Recently, we have established first contacts in China, because we would like to enter this large market. The greatest potential for us lies in the location-independent consolidation of information from manufacturing processes at production sites around the world. By continuing to internationalize step by step and networking process chains worldwide, we can create new added value and grow systematically.

According to your experience, how open are German companies to the use of AI software systems like Detact?

In Germany there are numerous companies that are open to such technologies. Many of them are quite willing to get involved in pilot projects. But there are also many companies that have reservations. After all, this involves fundamental decisions for the future that need to be very well thought out. Nobody wants to make mistakes, but in the long term, there is no way of getting around digitization. So we have to do a great deal of educational work: In numerous documents, lectures and seminars we present the opportunities and challenges of the new technologies and give interested parties the opportunity to react to changes step by step and to think through their own business processes. In 2020, for example, we are leading a special day on the subject of "AI in manufacturing processes", which is being organized by the VDI as part of the annual plastics conference. Of course, AI is a stimulating topic and many suppliers are trying to jump on it. For this reason, the term "artificial intelligence" can cover a wide range of products and services. It is no surprise that many manufacturers find it difficult to orient themselves and to get involved with individual solutions. Therefore, the most important thing is to find the right technologies for the respective concern. The more you know about the technological possibilities, the lower the entry level for a pilot project, for example. That is why we see it as our task not only to place our product, but also to inform companies about the potential of artificial intelligence and thus make the use of AI in production more socially acceptable.

How have you come to the Hub and how can the Hub support you in your further development?

We started talking at the event Hightech Startbahn in Bitterfeld. As a result, we decided to accept your attractive offer and to gain more visibility in the chemicals/health sector and in the Ludwigshafen area through the interview. The hub can support us in establishing contacts to other interesting startups and potential customers through the event, or even visibility through your network.

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!