One year after winning X-Linker: New pilot projects and product optimisation at PipePredict

Nine months is a long time, especially for a startup. Since our last article about PipePredict GmbH in May 2020, a lot has happened at the young company. PipePredict, that is the winner of 5-HT's X-Linker Programme 2020, which is now a year behind us. PipePredict, formerly known as Sooqua, makes it possible with its technology to predict pipe bursts and damage more accurately than any crystal ball. Today we take another look at predictive maintenance of pipes with co-founder Christopher Dörner and of course at the progress PipePredict has made in recent months. Christopher also wants to put out a call to startups, for example, from the field of sensor technology and companies with pipe networks.

The PipePredict founding team: Christopher Dörner, Valerie Fehst and Tri-Duc Nghiem (LTR)

The PipePredict founding team: Christopher Dörner, Valerie Fehst and Tri-Duc Nghiem (LTR)What happened so far:

Up to now, pipe networks have been maintained using preventive maintenance and a rehabilitation strategy. This involves calculating probabilities of when a component will fail or be damaged. The big disadvantage of this method is that it is not very cost-efficient because it only looks at the big average and not the individual component.

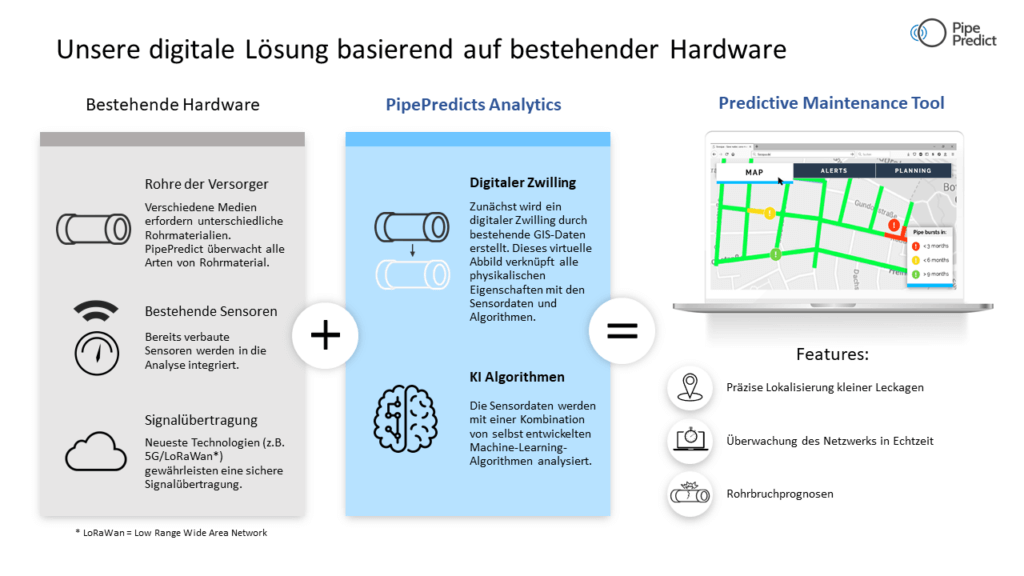

Using sensor data, PipePredict can determine the condition of pipes and thus make more accurate predictions than would be possible with the conventional method. To do this, the startup uses a digital twin, a 3D model of the pipe network, and has developed associated algorithms that can calculate predictions using the physical properties of the components stored in the model.

The startup was able to convince with this model: at 5-HT's X-Linker in February 2020, PipePredict won the first prize.

What happened for you after X-Linker?

"Shortly after the X-Linker accelerator program, we founded our GmbH. Meanwhile, we also started our first paid pilot project with a French district heating supplier. In the summer, we were ready to equip the sensor technology for the project. Our product was thereby verified on the market: We located three leaks at once for our customer in October with a precision of three metres.

The customer had not noticed these leaks until then, because there are actually permanently small leaks in district heating. As a rule, it is only for larger quantities detected that something is wrong, as the water make-up quantity increases sharply. In our three cases, the leaks were so small that the customer would not have noticed them at all based on the make-up quantity. This was very pleasing for our customer and for us, as we were able to localise leaks before they became larger and the damage thus expensive.

In November, we finally started our second pilot project: the project ran through a large sensor manufacturer whose contact we got through 5-HT and X-Linker. This is a pilot project in district heating, where leakages are to be localised with the help of sensor data. The project covers several kilometres of pipe network.

In December, we started our third paid pilot project in public water supply. Another one is already ordered for March. So we can look back on a whole series of pilot projects that we are carrying out with our customers as we continue to develop our product. This includes optimising the algorithms and adapting them to other networks - because every network has specific characteristics, different pipe types or even combinations or different pipe types."

PipePredict's digital solution based on existing hardware

PipePredict's digital solution based on existing hardwareDoes this mean that you want to expand to other industrial pipe networks?

"That is our goal. We see water networks as an entry market for us. The reason is that a leakage there is not explosive or harmful to the environment and at the same time - or precisely because of this - there are already many mainly smaller leaks that we can localise. So with this sensor data, we can train our algorithms better and thus advance product development faster.

After we developed the product for water supply, other industries are also interesting for us. For example, in industrial parks, not only water supply but also other liquids such as chemicals are of interest to us."

We talked about your highlights in the past year. Were there also low points?

"There actually were. Due to the Corona pandemic and related measures, we were prevented from going to our customer in France a few times. It was particularly challenging when we wanted to upgrade our hardware and were prevented from doing so for several weeks.

So we developed a way for the customer to make changes to the hardware himself and were able to bypass the problem that way. Still, direct contact would have been nicer, of course. That is the challenge of transnational pilot projects during the Corona pandemic. However, we have learned to carry out projects without having to be on site ourselves.

In addition, networking was more difficult: we took part in some competitions where, unfortunately, the award ceremonies were only held online. However, a large part of these competitions is networking, but that was only possible to a limited extent.

At the same time, this has also been an advantage of digitalisation, because we have been able to participate in international competitions. For example, we won first prize in the 'Brasil Sustentável' of the AHK Chamber of Commerce Abroad in São Paulo, which aims to make water supply networks in Brazil more efficient and reduce losses."

Are there any other competitions that you have participated in and won?

"We are also one of the winners of 'WeConomy', a competition organised by the Wissensfabrik in cooperation with UnternehmerTUM and Handelsblatt. As a winner, you not only get access to top managers of large companies, but also advice on business model development and sales.

We are also currently involved in the Leipzig SpinLab Accelerator, a program for the energy industry, which we also serve with our leakage localisation in district heating. The program runs from January to June and gives us access to a digital learning platform for start-ups as well as a coaching and mentoring program.

The funding programmes such as the Climate-KIC Accelerator have also gone digital, which has brought us surprising advantages: The bi-weekly meetings among the startups were digitised, so that all startups from the DACH region of Germany, Austria and Switzerland could meet and exchange information digitally. So we turned the disadvantages - as best we could - into advantages."

We have talked a lot about your past, the last year. But what do you want your future to look like?

"Our most important plan for the future is to develop a market-ready product. Of course, we want to bring the product to the market, distribute it and help many customers to reduce their losses and enable better planning of repairs. In the meantime, we have grown to six employees plus us three founders, but we want to expand further and build a sales team. On the technical side, we want to further optimise the product so that we can locate leaks more and more precisely and provide better algorithms.

And we are currently building up a partner network. That's why I would like to make an appeal to other companies: for example, startups that specialise in sensor technology and are looking for an application partner are welcome to contact us. I would also like to address large companies that have pipe networks, want to be able to plan their repair measures better, want to know the real-time status of their pipes or want to avoid production downtimes caused by leaks or pipe bursts: Feel free to contact us, even if you are not from the water networks sector. We offer a free initial analysis that determines how accurately we can monitor the pipe network with the sensor technology we already have."

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!