Robots with a human-like sense of touch

Katharina Kittelberger

How can productivity be maintained in the future economy when there is already a shortage of skilled workers due to the aging of the population? The Japanese startup XELA Robotics sees a need for action here. That's why the hard- and software company has been working on tactile sensor technology since it was founded in 2018.

With its uSkin sensor, XELA Robotics can thus offer a far-sighted solution to counteract the labor shortage in the future. For instance, Dr. Alexander Schmitz, CTO, also claims that "with uSkin, we can maintain the productivity of the economy, even if fewer people are available as workers."

The ambition to give robots the human sense of touch can potentially be used in many other areas besides assembly and packaging. In an interview with 5-HT, Alexander explains what these are.

Dr. Alexander Schmitz, CTO at XELA Robotics

Dr. Alexander Schmitz, CTO at XELA RoboticsGive us a quick elevator pitch: what exactly does XELA Robotics do?

"We develop tactile sensors that enable robots to perform tasks that previously could only be done by humans. This allows companies to automate their processes and allows them to save costs on personnel and reduce fulfillment time", Alexander says.

In more detail, he claims, "to make this possible, we've developed a high-density, 3-axis tactile sensor called uSkin."

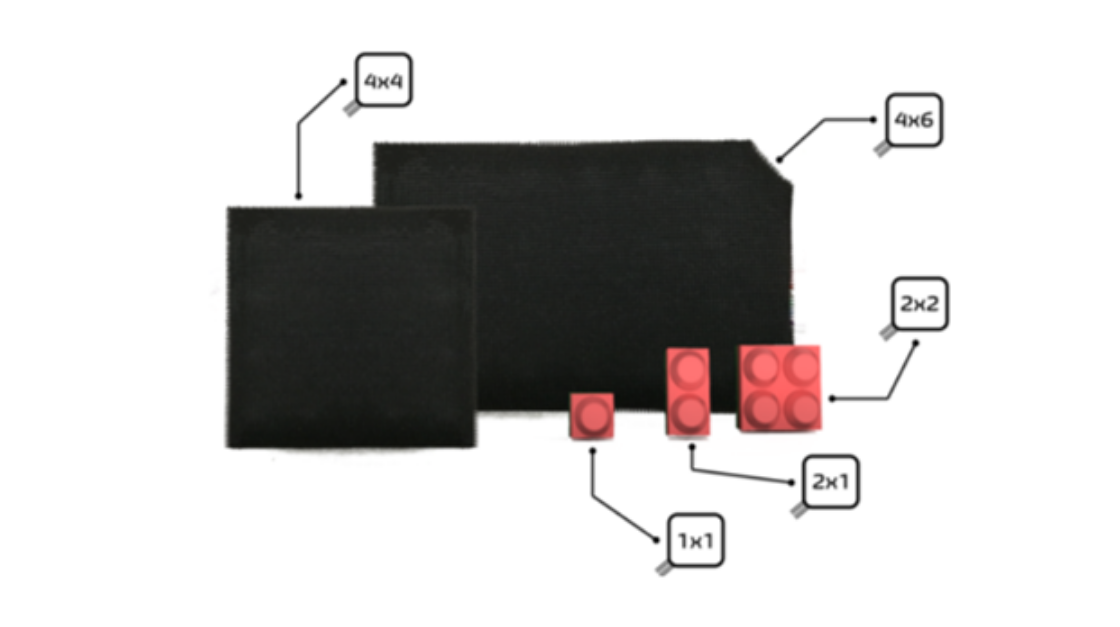

The tactile sensors in five different sizes and shapes for use in robot hands and grippers

uSkin - structure and implementation

"Our sensor is primarily composed of three components: First, the outer shell, which serves as protection but can also be modified for various applications. Secondly, the soft elastomer, which on the one hand ensures that the sensor is resistant to overload. On the other hand, it allows the sensor to adapt better to the objects a robot reaches for. The third component is the chip, which detects displacements in three dimensions. Each sensor module receives a number of these chips, each of which can measure the 3D displacement individually," explains Alexander.

Overall, the uSkin sensor is embedded into a thin, soft and robust housing. Its minimal wiring is unique, as this, along with its thinness of just 5.5 millimeters, allows for easy implementation into new or existing robots.

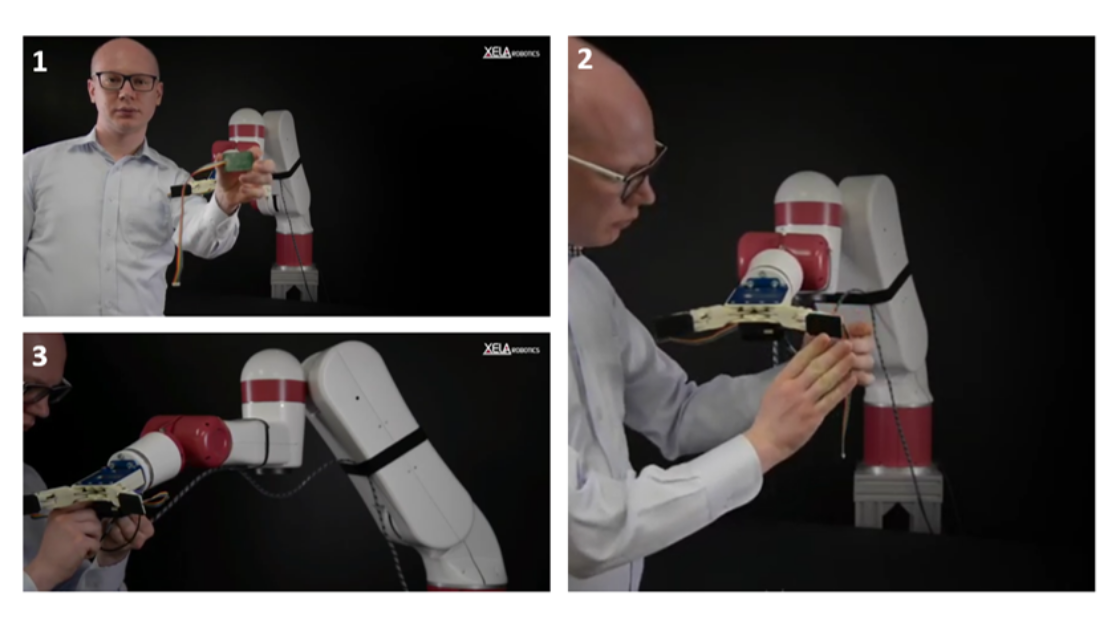

Alexander illustrates this clearly in the following graphic:

The implementation of uSkin in only three steps: 1. removal of the protective layer, 2. attachment of the sensor, 3. connection of the cable to the robot arm

This gives robots a human-like sense of touch, with which they can from now on grasp and manipulate objects with precision.

Where exactly does it make sense to use a robot with sensibility?

"Currently, many of our customers come from the assembly robotics sector," says Alexander. "But there are other application areas where a robot with sensitive motor skills would make sense, such as warehouse automation: Let's say we look at the classic ordering process of an online retailer. He, of course, has a large warehouse and with each incoming order, objects must be taken from various shelves and then packed into a box.

In general, our sensors can be used wherever the handling of fragile objects are involved.

Until now, only humans could perform this task, but with the help of our sensors, it will be possible in the future without their physical presence, because the robots have the same motor skills as humans," Alexander describes.

There are already manufacturers of tactile sensors on the market. What sets you apart from these competitors?

"Four features in particular set us apart: While other sensors require various cables and large analog-to-digital converters, u-Skin needs only a few thin wires and offers an exclusively digital output. This allows measurements to be made faster, more accurately, and with minimal electrical noise, which also prevents interference," Alexander said. "Second, our skin sensors can be easily integrated without proprietary connections. Thus, they can be either glued on or attached with appropriate brackets in a variety of ways."

In the near future, we will also develop tactile artificial intelligence. So, in the future robots will understand what they grab and be able to intelligently adjust their force accordingly.

Third, the soft uSkin sensor can reliably grasp and manipulate fragile objects of different sizes, shapes, hardnesses and weights - without damaging them, of course. "Likewise, the softness ensures that the sensor is enormously resistant to overload. This makes it enormously durable at the same time," adds Alexander. Ultimately, uSkin is less expensive - without compromising on performance.

What are you particularly proud of since the founding? Have there been any setbacks?

"In fact, everything has gone according to plan so far," laughs Alexander. "We can't complain about defeats, quite the opposite: Already in the first year after the foundation we had a turnover of about 100,000 €. The following year, that amount doubled, and this year we were finally able to show €400,000 in annual sales."

Despite the global COVID pandemic, we were able to double our sales - we are particularly proud of that.

In addition, XELA Robotics now has more than 50 customers on four continents. And the future promises growth: "Because the demand by our customers is increasing, we are currently in the process of producing our sensors in larger quantities. For this purpose, we have a partner in Taiwan. With the new mass production, we are better prepared for future large orders," says Alexander.

But Alexander also highlights the XELA Robotics team in this context: "Our international team now consists of nine employees, all of whom come from countries between Austria and Thailand."

XELA Robotics is based in Japan: What do you hope to gain from working with German accelerator 5-HT?

"I recently became aware of 5-HT through my participation in one of your startup contests. When I was subsequently contacted and saw your large network of diverse startups and companies, I was immediately excited and saw many opportunities in our cooperation."

A young startup like XELA Robotics sees great opportunities in 5-HT being able to connect us to big companies.

So, Alexander is also confident about future cooperation with 5-HT in the healthcare and chemical industries: "Because we see many opportunities to get involved in these two industries in the future, we hope for intensive cooperation with 5-HT."

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!