ZReality and BASF - Innovation projects in augmented reality within reach

Corinna Herrmann

Interview with Adrian Dietrich ZReality and Benedikt Wagner BASF – When the right partners meet and the requirements are clearly defined, innovative projects can be implemented quickly. The teams from BASF and ZReality proved this and built a virtual showroom within a few weeks to make current innovation projects exciting and tangible for BASF employees. In an interview with 5-HT, project managers Benedikt Wagner from BASF's Business Innovation Team and Adrian Dietrich, Head of Sales and Marketing at the startup ZReality, a software platform for virtual reality, augmented reality and cross reality apps in the industrial sector, talk about their experiences.

5-HT: What does ZReality do?

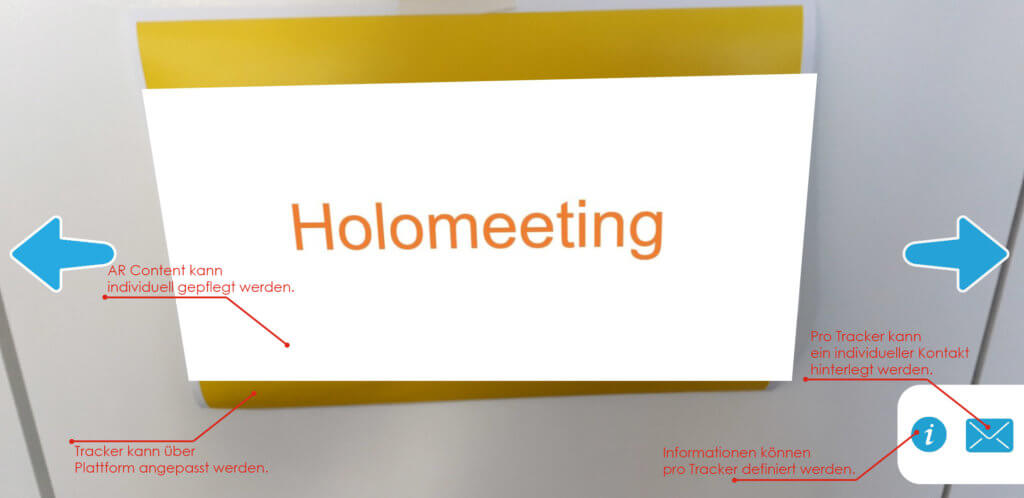

Dietrich: As a startup, we developed an application where you can easily add AR content via our platform, i.e. you can upload content such as photos, videos or 3-D models yourself, merge them with a tracker in our platform and can build a separate showroom for practically every use case.

The AR app recognizes any tracker and displays content that can be defined via the ZREALITYsphere platform.

The AR app recognizes any tracker and displays content that can be defined via the ZREALITYsphere platform.5-HT: How did the collaboration between you come about?

Wagner: We got to know ZReality in June 2019. During the interview I presented my idea of presenting BASF’s internal innovation projects in a vivid and tangible way at our employee event in the USA. Since the event was already scheduled at that time, ZReality had to have its application ready by July 2019, just a few weeks later when the order was placed, so that we could show it. The schedule was ambitious, but ZReality assured us credibly that we would be able to implement it on time. So we placed the order.

Dietrich: The initial contact between ZReality and BASF was made through the 5-HT Digital Hub, which has already resulted in several Projects. The first meeting with Benedikt Wagner was very constructive and the topic of AR connections is part of our roadmap for our platform. Since BASF offered us an opportunity here, we spontaneously decided to bring this step forward. The great thing was that we were able to develop this AR application together with Benedikt and BASF as partners with short sprints within four weeks. The collaboration also went smoothly and constructively. For example, when we needed feedback, we called Benedikt briefly and he explained his wishes to us, so that we could also adapt the AR application very quickly to the specific needs of this project with our team.

Wagner: From our side, too, I can emphasize that the cooperation worked out super, because both sides were committed to implementing the project on time and with the best possible content. The solution is very simple for the user, because he does not need any deeper technical knowledge, but can easily integrate the content to be used into the AR application of ZReality via drag and drop.

5-HT: What can your application be compared with and where can it be used?

Dietrich: We can perhaps best compare it with Amazon. There, too, I simply upload the product I want to display, I write the text I want to display, I define what I want to display on the tracker and save the whole thing. Afterwards it is immediately transferred to the application. Anyone who opens the application on the smartphone will see the data live, because it is downloaded directly to the smartphone via the Internet connection and is always updated live if something is changed in the application. This means that AR content can not only be used for these showrooms, but that content can also be displayed on a system such as operating plans, operating instructions or safety steps to be followed.

It is also possible to identify a specific part of an installation, such as a control panel. When an employee photographs this and the image is uploaded to our platform, the corresponding instructions can be saved. Every time a BASF employee would hold the application over this panel, he would then be shown the pdf with the safety features. It is therefore transferable to all other cases. I could even integrate live data via interfaces.

Any content brings a topic to life in Augmented Reality. BASF employees can contact the project managers directly via the AR app.

Any content brings a topic to life in Augmented Reality. BASF employees can contact the project managers directly via the AR app.5-HT: What is the advantage of AR application and what is the next step in the collaboration?

Wagner: There will definitely be more projects like this event next year. At BASF we have a lot of virtual topics. One example is Blockchain. This virtual construct can be explained much better with virtual possibilities than simply putting a chain on the table. On a tablet I can insert animations or show further information. This is easier for the user to understand. At BASF, for example, we have relatively many virtual projects that cannot be displayed physically. But we use this tool to enrich our events and exhibitions with further information. Of course, we are also pursuing the gamification approach. The user should have fun trying it out. Thus, the content is presented in a more relaxed and exciting way than just running a PowerPoint presentation or a video.

Dietrich: By putting the smartphone in the user’s hand and sending him off to explore the room with its contents on his own, he is first of all in the playful thought. The learning theory also confirms that I am more open to new things in a playful way and, in this case, more willing to explore this space. The explorative is then the interesting thing, because one has to discover the trackers and is always activated anew by new content. This is exactly the advantage of this application compared to static applications like a PowerPoint presentation.

In Business Innovation Management at BASF, there are so many topics currently running that I can address with short teasers using our application. Anyone who would like more detailed information can do so using the content provided in the exhibition or even contact the person responsible for this project directly via the AR application. To do this, I simply press the word contact and can write a message directly to the person responsible in the USA “Hello, my name is Adrian from Ludwigshafen. I heard that you are doing something great about Blockchain. Can we talk about it?” Then this contact person will receive an e-mail directly into his mailbox from the AR application. Business Innovation Management at BASF thinks beyond structures and also networks sites. That’s the exciting thing about this application: not only are things displayed here, but people can also be networked with each other via this AR application.

5-HT: What role does the 5-HT Digital Hub play for you in your collaboration with Corporates?

Dietrich: Benedikt was one of the initiators for this application and this concept. For us as a startup, it was very pleasant to experience during the cooperation that even a large corporation is very innovative and in short sprints and that it is easy to get in touch with each other. The courage that is shown here is something that a start-up company would like to see in other places as well, in order to try out something new. So it was good for us as a startup to be a partner of the 5-HT Hub, because it also means a certain standing within the company. We have been monitored as partners before, we have been taken under the wings and we have been checked if we can keep our promises. There are many start-ups with good products. But if you are chosen as a partner of a digital hub, it also means a certain amount of trust in a corporate.

At BASF, we have been able to prove that we do the things we promise. Getting a first prototype up and running within four weeks was ambitious, but it was nice to implement.

5-HT: What is your conclusion and how do you intend to proceed?

Dietrich: We received feedback after the first event, which we then incorporated with the functionalities. The goal is to establish an exhibition every two weeks at the various BASF sites next year. The advantage of this application is that external content does not have to be reprogrammed each time, but that BASF employees can define content themselves and build their own AR application within a few minutes without having to spend several days on implementation by an agency.

Wagner: That means an enormous saving of time and costs for all participants due to this platform character. This is also only possible because the application is so simple and easy to understand for the end user, who does not have much experience with coding. There is a form into which I can upload my data, i.e. both what should be displayed and the tracker. These trackers don’t necessarily have to be QR codes, but for example a picture or an attachment or something similar. It is important that I link tracker and content together. These are the steps I have to take. There are a few small settings that you can make, such as defining an email address for the contact button. It was very important to us that the application is easy to use and that you don’t need a lot of training. A briefing of maximum 30 minutes is sufficient, but it would work without.

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!