Tightening the screws on process monitoring: Continuously possible with Sensorise' digitized micrometers

Ronja Schrimpf

Micrometers are nothing new in process monitoring - but the previous standard weakened the screws by requiring them to be drilled into, and only allowed for recurring measurements. The startup Sensorise, on the other hand, enables the digitization of machine elements, which allows continuous monitoring - and thus also approaches process optimization.

In an interview with 5-HT, managing director and founder Cord Winkelmann talks about the advantages of continuous screw monitoring.

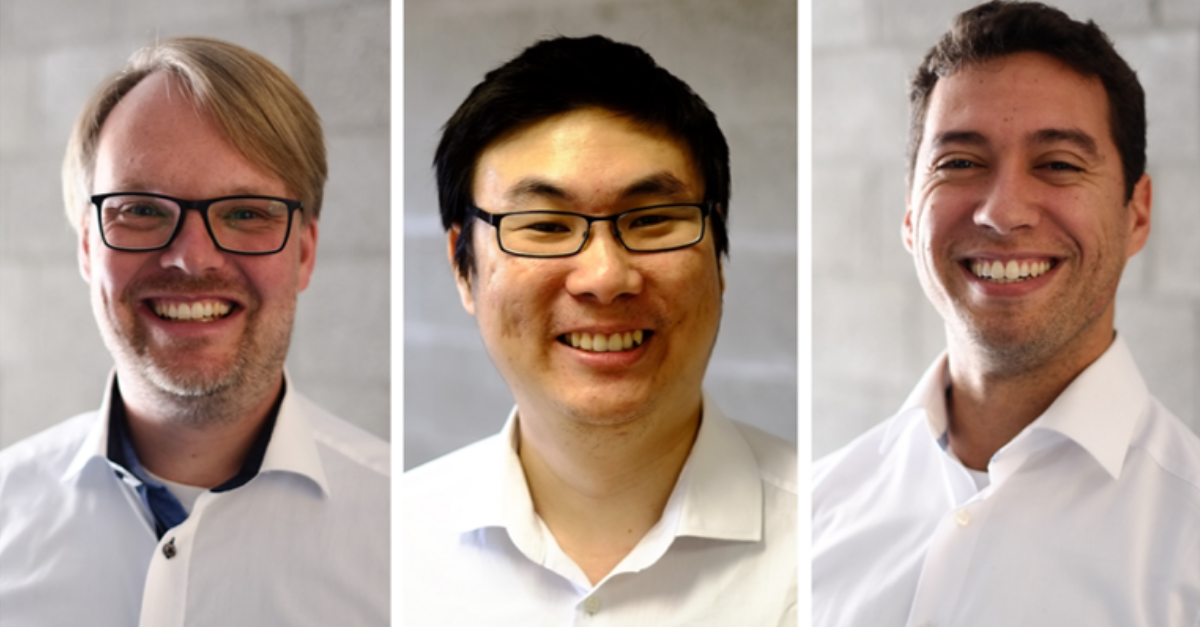

Cord Winkelmann, one of the three managing directors and founders of Sensorise

Cord Winkelmann, one of the three managing directors and founders of SensoriseScrewing on the digitization of machine elements

"We digitize machine elements, mainly screws. This enables us to continuously monitor screws and everything that is held together with the screws," Cord Winkelmann summarizes. "We can thus monitor wear conditions and processes, for example."

So far, it has already been possible to monitor screws using ultrasound. "However, these are periodically recurring and not continuous measurements." It is also necessary to be on site. Unfortunately, it is not possible to trace what caused the screw to loosen - a disadvantage that Sensorise compensates for with its technology.

Gauging screws themselves are also no longer a novelty. Usually, a hole is drilled in the center of the screw along the screw axis and a strain gauge is bonded there. "In this case, there is always a weakening of the screw, because material is taken away from the screw. Sensorise just doesn't do that - our screws have the same strength values as an unmachined screw."

The team of Sensorise (f.l.t.r.): Cord Winkelmann, Kaven Henry Yau Wong und Rodolfo Faria

The team of Sensorise (f.l.t.r.): Cord Winkelmann, Kaven Henry Yau Wong und Rodolfo Faria Screwing at the tolerance range of screws

Only at the top of the screw, which is usually unloaded, does Sensorise attach a bushing for signal transmission. To enable continuous monitoring of the screws, the startup uses the air between the screw and the nut: "We wind a thin sensor wire into the thread base of the screw. In doing so, we use the tolerance range between the core diameter of the screw and the clear diameter of the nut - the area where there is normally only air." Sensorise's sensory screw is thus modeled on an ordinary standard component and can be replaced 1-to-1 in existing constructions and systems. This is because with the sensory screws, the sensor element (= wire) and screw are an inseparable unit.

Screwing the inspections of plants

Sensorise's solution offers a number of advantages for companies: "It starts with the question of whether my screw is still stuck or not. As a rule, this is checked via recurring inspections - sometimes even machines or entire machine systems have to be shut down for this so that the inspectors can move around safely. Depending on the application, this recurring inspection can be very expensive.

So we offer the advantage of enabling continuous monitoring and thus saving these inspection rounds. In addition, we simultaneously measure the dynamics of processes, for example long-term dynamics such as temperature-related changes in the screw or short-term dynamics caused by processes such as vibrations. By measuring the dynamics, we can detect indications of damage much earlier. Through an external inspection, these indications are not visible at all or much later."

But measuring dynamics has other advantages: "Dynamics also gives me the opportunity to look inside a process. If the processes are cyclical, we can see from the dynamics whether the process is running as planned - or whether there are problems, for example, if wear is becoming apparent or if something is wrong with the quality of the process. These are the kinds of factors Sensorise can monitor."

Screwing with the monitoring of flanged joints

The areas of application can be very broad, as Cord makes clear: "Many screws are found, for example, in wind power - rotor blade screwing, tower screwing, etc. - but also in tunnel boring machines or in the construction sector. There, everything can be found in the area of infrastructure from bridges to tunnels to industrial buildings with crane systems and the like. There are also many screws in the production of the automotive industry that we can monitor."

But of course, Sensorise is also extremely interesting for the chemical industry: "In the chemical industry, we have screws mainly in flange connections, especially pipe flanges. With the help of Sensorise, it is possible to determine whether there are leaks or whether the flange is still tight. When I run dynamic processes in this area, it's also important to see if the process pressures are being maintained. These factors can be monitored through places that have not been thought of before - namely our digitized screws."

The Sensorise SmartScrew

The Sensorise SmartScrewShut-off valves can also be monitored through Sensorise: Are there blockages? Is there wear in the seals? "It's hard to judge that from the outside. With our solution, you can look inside components very well."

Screwing the machine elements in 5-HT's network

To date, Sensorise has a diversified customer base from numerous sectors. Among them are many international customers, including from China and South America. With 5-HT's network, the startup hopes to tap into the process industry. "In the process industry, there are many flange connections for which we are predestined with our digitized micrometers." In addition, the topic of process monitoring is a particular focus in the process industry: "There, we can fully exploit the strengths of our system. At the same time, this is a sector in which we have only had a few customers so far - this is also due to the location." After all, Sensorise is located in Bremen, where there is comparatively little process industry. "That's why 5-HT is an exciting network for us."

Screwing on a startup for micrometers

In Bremen, Sensorise currently consists of three employees. Cord originally comes from the field of mechatronics, microtechnology and information systems, so he covers the systems thinking. The team also includes a physicist who specializes in data evaluation and software development, as well as a chemist who is focused on sensor development.

"Sensorise itself is part of the Proekspert Group. Sensorise was founded in 2019 when the Proekspert Group scouted in the field of sensor development. For Sensorise, being part of Proekspert has great advantages. With its more than 200 employees, Proekspert has a contact person for every area, and I can approach them with everything from marketing to accounting to data science. That works great for us."

Screwing the future of Sensorise

"At the moment, we are heavily involved in the project business. We want to address the issue of automated manufacturing with screw manufacturers in particular, so that we can offer larger quantities at lower prices. Along with that, we want to move further away from being a sensor and hardware manufacturer to what we do best, which is data analysis and software. This should give customers more advantages in the direction of data science."

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!