Risk management: From the supply chain to the value chain

Katharina Kittelberger

Whether it's storms, floods or traffic disruptions, geodata can help companies better assess and respond to risks to their supply chains. This is where the startup Orbica comes in. It is part of the 5-HT network and is developing a supply chain risk management system based on geodata. In the interview with 5-HT, Matthias Frye, Marketing and Sales Manager for the European market, explains how this solution differs from existing ones and how companies can use it to reduce risks not only for their supply chain, but for their entire value chain.

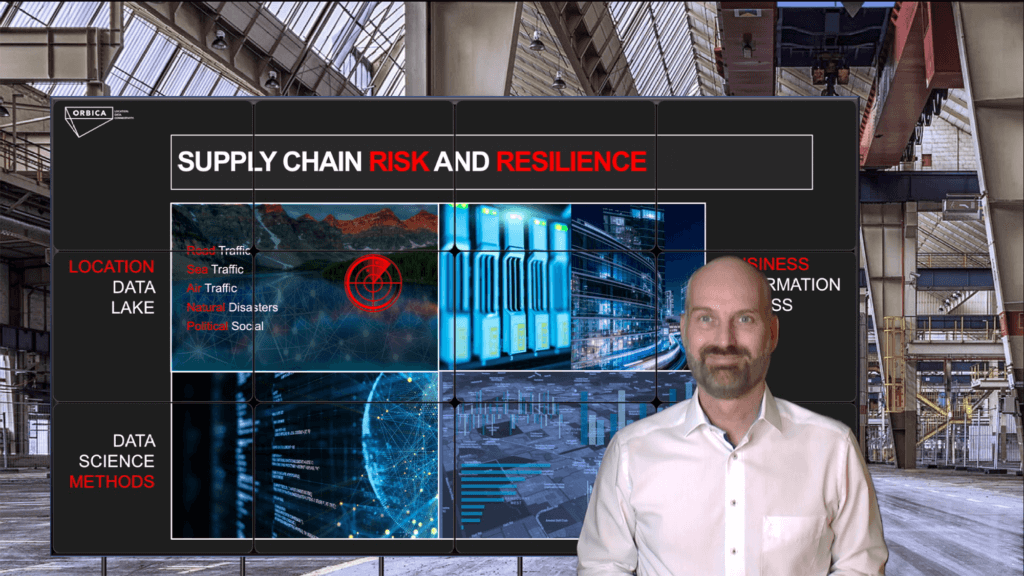

Matthias Frye from Orbica

Matthias Frye from OrbicaWhat is the idea of Orbica?

Orbica was founded in 2017 on the idea that while there are already many startups working on Big Data, one issue is being overlooked: location. So we started thinking about how we could take this approach and develop a practical solution for the industry. We realised that we could use geodata to enable companies to better respond to pandemics, storms or other events that could threaten their supply chains. In doing so, we aim to help our clients improve their supply chain risk management.

How can the analysis of geodata contribute to better supply chain risk management?

With the help of geodata, we can record a variety of risks - on the one hand, natural events such as earthquakes, storms, floods and weather conditions, but also traffic disruptions, delays in customs controls or similar. We work with various partners to access this data. HERE, for example, provides us with data on global road traffic, and Spire provides us with data on maritime and air traffic and weather data based on satellite observations. For natural disasters, we draw on various sources of information, such as NASA's satellite data. We are also currently building a partnership with DHL Resilience360, a supply chain risk management software that enables DHL to make external causes of disruptions to its own operations accessible to other companies. With this variety of sources, we are very well positioned in terms of capturing transport risks.

How does supply chain risk management work with Orbica - and what distinguishes you from the existing solutions on the market?

We offer a cockpit application in which the company's entire flow of goods is visualised on a map. As soon as there is a disruption that could affect a delivery, a warning message appears that you can click on to get more details. We are not the only ones with this approach, but we go a big step further than other supply chain risk management systems. Most of these systems only assess which suppliers have a risk on the transport route. Then the companies themselves have to painstakingly research what it means for them if supplier XY has problems with his plant in the USA. With Orbica, this effort is eliminated because we already include data from production planning and inventory in addition to external risks. This allows the company to see immediately whether a transport risk is highly relevant because it might lead to a production stop, or whether it is negligible because a second delivery from another supplier arrives a week later. Thus, we move from the supply chain to the value chain by visualising directly in our solution the risk to the company's value creation.

How can companies benefit from this information about their risks?

On the one hand, this enables our customers to cushion existing risks. On the other hand, they can also preventively ensure that their supply chain becomes less susceptible to disruptions. To find the right optimum between a lean and a resilient supply chain, we offer simulation-based scenario analyses: In our solution, our customers can have it modelled what would happen if they were to change various aspects of their supply chain, for example if they were to commission an additional supplier or set up an interim warehouse.

For which companies is Orbica's supply chain risk management solution relevant?

Our solution is relevant for all companies that have many physical goods transported through a large network of supply chains. This applies to the retail industry, but also to the manufacturing industry, which depends on its production lines not coming to a standstill. This of course includes the chemical and pharmaceutical industries. Supply chains are particularly sensitive in the chemical industry because transport disruptions, for example with hazardous goods, can cause considerable difficulties.

How far along are you with the development of your solution?

After conducting a supply chain risk optimisation assessment for an international conglomerate in the technology, healthcare and energy sectors, which gave rise to the specific idea for our solution, we have now developed a proof of value that shows our approach works. Over the last twelve months, Orbica has grown significantly. We are now 25 people, most of whom are based at our founding location in New Zealand, but also some at our new location in Berlin. We finance the development of our solution with other contracts where we use our expertise in dealing with geodata. For example, we developed an interactive map for BASF to visualise sustainability projects. For our supply chain risk management solution, we are currently also working with many different partners, for example with leading software providers for data integration (Alteryx and Safe Software) and data visualisation (Qlik) and with technology providers for geodata (ESRI and mapbox). So we rely very much on an ecosystem that supports us in technical implementation and also in access to customers.

What are the next goals for Orbica - and how can 5-HT support you?

First and foremost, we are currently looking for one or two key customers who would like to accompany the development of our product as early adopters, so that our solution is actually developed out of practice and for practice. In this way, we offer interested companies the opportunity to influence our solution and ultimately receive a product that is 100 per cent tailored to their requirements. We are also pleased when we come into contact with potential investors or technology partners through 5-HT, for example in the area of tracking. In addition, it is always exciting for us to exchange ideas with other start-ups in the areas of logistics and supply chain.

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!