More accurate than the crystal ball: Predicting leaks in pipe networks digitally

Ronja Schrimpf

Every company in the chemical and pharmaceutical industry needs them. Every water or district heating supplier needs them. Yes, just about every company in the manufacturing industry needs them: pipes. They transport the resources needed for production, cooling or supply. If a pipe is damaged or even breaks, a company faces high repair costs, the loss of valuable resources and possibly even a production stoppage.

And the solution? The startup PipePredict GmbH - formerly known as Sooqua - with its proprietary technology that allows for accurate prediction of pipe bursts and damage. In an interview with 5-HT, co-founder Christopher Dörner, the lucky winner of the first prize in this year's 5-HT X-linker , reveals how this works, what advantages companies can expect from PipePredict and how a startup can cope with the corona crisis.

Christopher Dörner

Christopher DörnerHow is pipe damage predicted so far?

"Currently, a rehabilitation strategy is being developed and preventive maintenance for pipe networks is being carried out. This involves using statistics to estimate when a component will fail. But these statistics only consider the big average and not the individual component. This means that the component could break down before the average value or even survive undamaged for a longer period of time, but will still be replaced. Both cases are not very cost effective.

That's why people today try to determine the exact condition of individual components with the help of sensor data. Using this sensor data, one can then predict when the individual component will break. So if something in the components of the pipe network deteriorates, this is immediately included in the calculation."

And that's what 'PipePredict' does. What exactly does your technology look like?

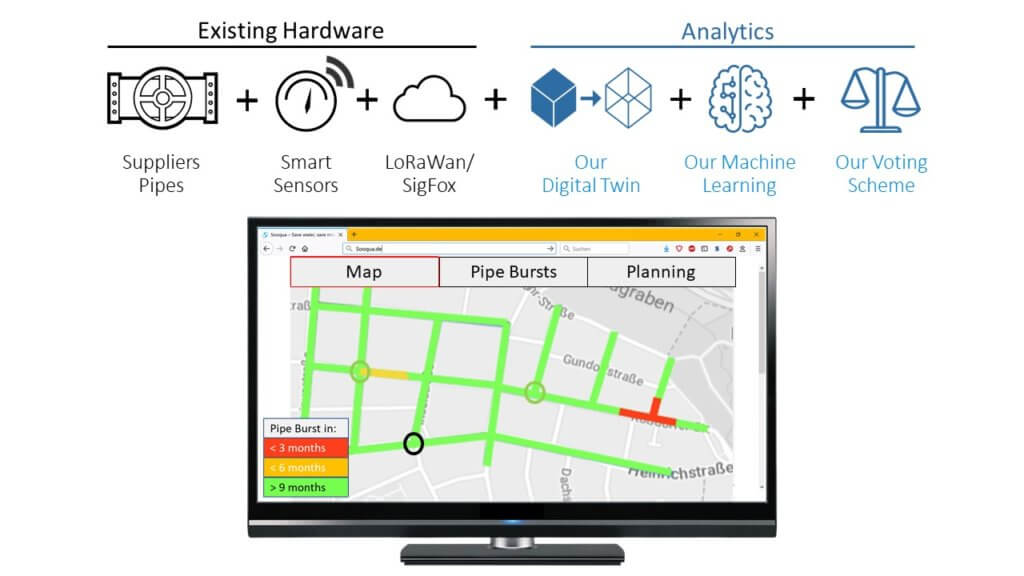

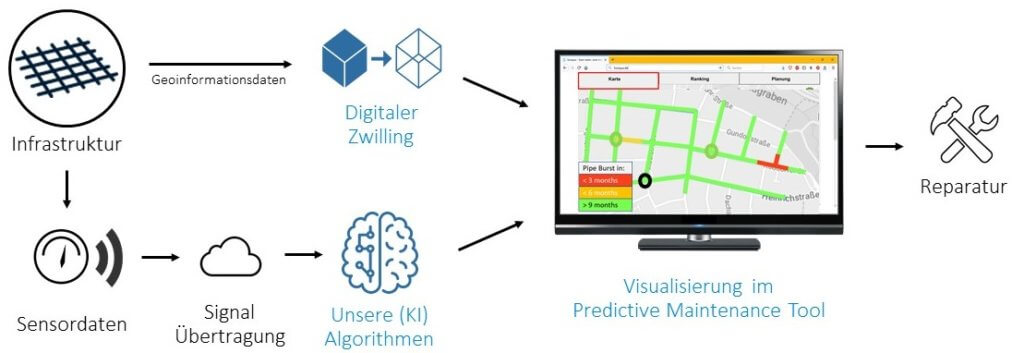

"We use a digital twin, a 3D model of the pipe network. This model contains all the physical properties, such as the diameter, material and age of the pipe. In this digital twin, we analyze the sensor data with the help of our self-developed algorithms. This enables us to precisely locate where there is already a leak and predict when a pipe will burst.

In other words, PipePredict does predictive maintenance for pipe networks. Predictive maintenance is the basic term for predictive maintenance. This means that we always know, based on real-time sensor data, what the current condition of certain components in the pipe networks is and when a failure will occur.

PipePredict offers Predictive Maintenance for all pipe networks that transport liquids or gases under pressure. However, for the time being we have concentrated on water networks, i.e. water networks for public water supply, district heating and for cooling and production in industrial parks. We started with water as a medium because it is non-toxic, explosive and dangerous, and thus provides the optimal training environment for our algorithms. But basically we can do predictive maintenance for all pipe networks. That's why we are currently in talks with companies in the chemical and pharmaceutical industries."

And that's probably why you're in 5-HT's network, right?

"Exactly. At 5-HT, we are looking for contact with companies in the chemical and pharmaceutical industry who are interested in working with us. We would be very happy about another pilot project in an industrial park. First of all, we would monitor the water networks and thus prove how accurate our predictions are and how much can be saved. This could later be transferred to other media needed for production.

We have already taken part in several competitions and 5-HT's programme was one of the best. It's specifically designed to help startups network with companies and win pilot projects - or quickly notice if it doesn't fit between the start-up and the company.

Through 5-HT we have been able to talk to a number of companies and we still have contact with two of them. One of them would be a potential partnership with a sensor manufacturer and the other would be a pilot project with a large chemical company."

Your digital solution will probably require a lot of sensors in the pipe networks. Is this infrastructure already in place?

"Unfortunately not as often as we would like and not in the number of sensors we need for accurate prediction. With the existing sensor technology we can usually already offer general monitoring of the pipe network, but the more sensors you have, the more accurately you can locate a leak. We also combine pressure, flow rate and acoustic sensor types.

At the beginning of a cooperation we first take stock of how many sensors of which type and at which position are already available. This is very dependent on the respective network. For example, drinking water networks already have flow rate sensors at the entrances to the different pressure zones to better control pumped-in water. In addition, more and more smart sensors are being installed in smart cities, which serve as water meters and can be integrated into our system. They are already sufficient for monitoring the pipe network. In addition, water suppliers have often installed pressure sensors, but not in the quantity we need. However, this can look quite different with other networks.

After taking stock, we advise the companies on which sensors from which manufacturer and type would be most suitable and most cost-effective. In this way, we ensure that the lowest possible investment costs are incurred for the precision in leakage localisation required by the customer".

Is your technology already proven in practice?

"We currently have a pilot project with a French utility company in the district heating sector. We're monitoring several kilometers of pipeline network in real time. We also have two other pilot projects in the pipeline - but due to the current situation caused by the corona virus, we can't yet say whether the projects will come to fruition. Especially since a second customer is also located in France."

How does the corona crisis affect a startup like yours?

"Before the Corona crisis, we were very well supported by the economy. We received several support programs and have been able to work full-time on our company since the beginning of 2019. At the moment, however, we are wondering whether this will continue to be the case. Will there continue to be so many support programs? Will the economy continue to develop this way? Will there still be private investors?

As a startup, we have to assume that large companies will pull out and less frequently bring in innovations like ours. And we have to ensure our own survival. In addition, startups do not have very many financial reserves. This makes it especially difficult for a startup at this time."

The PipePredict team consists of you, Valerie Fehst and Tri-Duc Nghiem. How did you three come to the decision to form PipePredict?

"It's a longer story. It begins with Valerie developing a pattern recognition algorithm. During her time as a data scientist at an IoT start-up, she worked with Tri-Duc, our computer scientist and machine learning expert, on a project for a water company. At that time, she discovered that her algorithm for water networks works much better than the traditional methods used to locate leaks.

Team: Christopher Dörner, Valerie Fehst and Tri-Duc Nghiem

Team: Christopher Dörner, Valerie Fehst and Tri-Duc NghiemWith physics and computer science, Valerie and Tri-Duc come from very technology-oriented backgrounds, so they were looking for a third person for the business field - and that was me.

In the beginning our startup was still running under the name Sooqua, but then we decided on a clearer name that was easier to pronounce and remember. We are now called PipePredict and we officially launched the start-up on March 6, 2020."

What was your personal motivation to get involved with a startup like PipePredict?

"Even before PipePredict, I was involved in the application of Predictive Maintenance during an internship and in my master's thesis, but in the area of production plants. Even then I found Predictive Maintenance a very interesting topic. In addition, during my studies I focused on IT entrepreneurship, including the founding of start-ups. With PipePredict, the two came together and fitted together perfectly.

In addition, for me, predictive maintenance has had a great influence on mankind. Because water stress will become a big problem in the next few years. So if we can help to reduce water stress and water poverty, then we'll be happy to do our bit to make the world a better place.

Does that mean you want to enter the international market?

"We chose Germany and France as our entry markets, because these markets are naturally closer and we are more familiar with the mentality and legal situation. But in the longer term, we also plan to operate internationally. Many markets are particularly interesting for water supply: South Africa, for example, which in 2018 had almost Day Zero, i.e. the day on which the demand for water is higher than the possible supply.

And PipePredict would of course help to prevent such a Day Zero. What are your plans for the future?

"First of all, we want to further develop our product with customers and apply it to various industries - initially primarily for water networks, from district heating to fresh water to industrial parks. That's why it's important for us to implement pilot projects in the same and different industries this year so that we can compare how much of our software still needs to be adapted. We are also planning follow-up financing by investors at the end of the year.

Over the next few years, we want to adapt our algorithms to other media, i.e. to chemicals, gases and other liquids. And then we also want to gain a foothold in international markets. And, of course, we also want to do something good for the environment, because if a pipe bursts, the energy that was needed to extract, process and transport the liquid or gas is also lost. So we want to offer a resource-efficient, but also economic added value. We compare the value of the amount of water lost with the repair costs that would be incurred to repair the leak. This enables us to tell the water suppliers exactly at what point in time a repair is economically viable".

So what would you like to offer our readers?

"All companies that would like to make their supply networks resource-efficient and economically efficient are welcome to contact us. Smaller pilot projects are also possible. For the time being, we can demonstrate how precisely we can locate and predict leaks and how much a company can save by doing so. There is also the possibility that a pilot project with PipePredict receives additional funding, because the federal and state governments have special funding programs for projects in which companies want to save resources or CO2".

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!