Industrial AI Solutions for the Manufacturing Industry

Judith Hillen

With Tvarit, a startup from 5-HT’s digital ecosystem, manufacturing companies only need a few weeks to deploy AI solutions in their production plants. For use-cases like OEE optimization, process optimization, or predictive analytics, the Frankfurt-based startup offers customized and industry-specific AI solutions. In this interview with 5-HT, CEO and Data Strategy Expert, Suhas Patel explains how Tvarit manages to minimize the risk for its customers and, thus, supports them on their road to AI-driven digital transformation.

Tvarit: Suhas Patel (CEO) and Rahul Prajapat (CTO)

Tvarit: Suhas Patel (CEO) and Rahul Prajapat (CTO)What does Tvarit do?

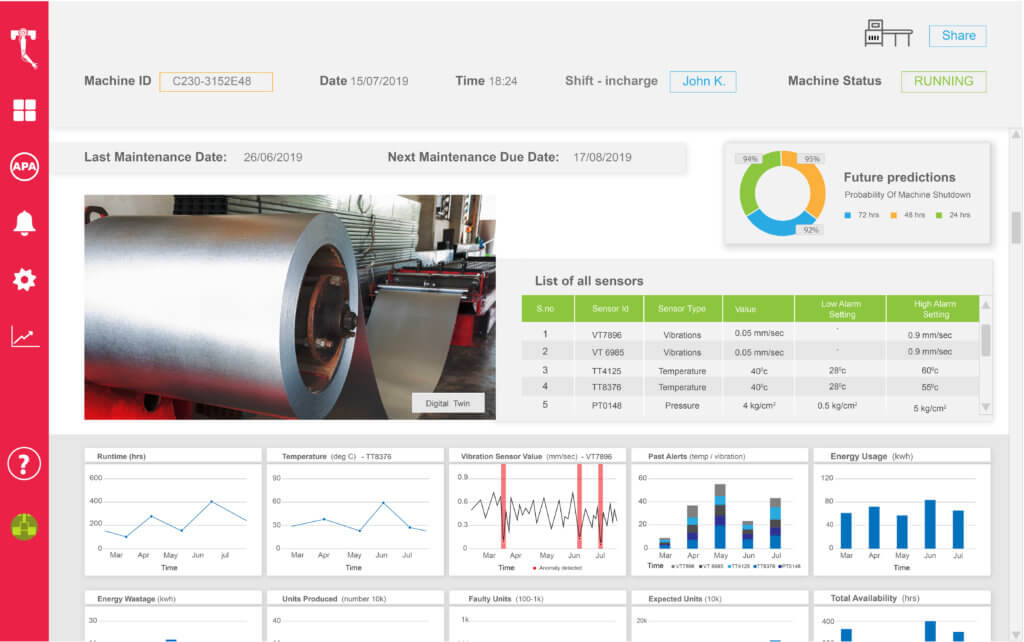

We have developed an industrial AI platform with 100+ algorithmic modules for very niche use-cases of the manufacturing industry. The algorithms have the capability of automating tasks like data preparation, data understanding, feature engineering, predictive analytics, evaluation, and risk management. They are fine-tuned for manufacturing-related use-cases and provide an end-to-end solution from data collection to visualization – all within a very short time period of eight weeks.

Tvarit_Software_Screen

Tvarit_Software_ScreenWhat features does your AI platform include?

We offer functionalities like What-If Analysis, Root Cause Analysis, Lag Analysis, etc. In case the monitored values go out of range, the users receive alerts, and our platform also gives them recommendations and prescriptive analysis of actions to be taken. Because there are many different groups of people involved, e.g. the production manager, the shop floor manager or the C-Level executives, they all get their individualized dashboards, visualizing KPIs they are interested in. Moreover, they can communicate with every machine and get a 360-degree visibility of the shop floor through our customizable dashboards.

Who are your customers?

Since we are a German startup with roots in India, our customers are mainly based in Germany or India. At the moment, most of our German customers are renowned automotive companies and machine builders. They are using our solution for quality optimization, OEE optimization, and scrap reduction. We are serving several companies from the chemical industry in India as well. In this area, we have already implemented AI-enabled solutions for energy optimization, quality optimization, and production optimization. Recently, we also connected with DECHEMA Gesellschaft für Chemische Technik und Biotechnologie and started talking with various companies from the chemical industry in Germany.

How does the process work when a company is looking for a Tvarit AI solution for a specific problem?

So far, we have developed six ready-made solutions: quality optimization for chemical processes, energy optimization for the steel industry, predictive maintenance for industrial motors, production planning for the cable industry, quality optimization for cold forming machines, and OEE optimization for butt-welding machines. When we already have a ready-made solution for a specific problem, we can easily integrate it within four weeks, as after data extraction we only need to fine-tune it to match the requirements.

If we need to develop a new solution, we follow a defined process that takes only eight weeks. In the first two weeks, we identify the business use case, break down the KPI objective, and extract and integrate the necessary data. Within the following four weeks, we develop the AI solution after preparing, harmonizing, and labeling the data. Finally, the last two weeks are spent with risk analysis: we measure the impact of the AI-driven decisions in terms of financial and non-financial benefits, and we identify closed-loop learnings to be incorporated into the AI model.

What are the key benefits for your customers?

With our clearly defined process, we shorten the time that is needed to develop and implement an AI solution, which reduces the costs for our customers. Furthermore, our pricing is designed to minimize the customer’s risk. In the beginning, we define a KPI objective that we promise to achieve with our solution. In case this objective is not met, we guarantee not to charge the customer. Companies in the manufacturing industry are often facing the challenge that they don’t know for sure if an AI solution will deliver the results they are hoping for. With our pricing model, we take away this risk from their shoulders.

How did Tvarit get started?

I have been living in Germany for 15 years, and I already had some experience in building startups before founding Tvarit. In 2016, I met Rahul Prajapat, a technocrat from the Indian Institute of Technology (IIT) Bombay with vast statistical analytics experience, including a project with NASA. During my entrepreneurial journey, I had built manufacturing units in the field of chemicals and densified biofuels. Together, we started thinking about developing a manufacturing-related product using statistical analysis. In 2016, Tvarit was conceptualized, and two years later we had our first customer. Today, we are headquartered in Frankfurt, with Juergen Halt as our Head of R&D. In total, there are 26 people working for Tvarit: 14 of them in Germany and 12 in India. Currently, we are expanding our teams both in Frankfurt and in Mumbai. Furthermore, we are very proud to have been selected as one of the 8 winners among 490 European companies in the experiment phase of the European Data Incubator (EDI) 2020.

What are the next goals for Tvarit?

At the moment, we are working together with many partners, e.g. with a cloud solution provider or with Intel and IBM on their on-premise solutions. Our goal is to deliver end-to-end solutions within these partner ecosystems, so that we can expand the pipeline in one place. Furthermore, we are developing new solutions which can give measurable benefits to the individual production plant. So far, we already have six ready-made solutions for specific problems in different industries. By winning new customers and strengthening our collaboration with industry experts, we want to gain an even deeper understanding of industrial use cases and create new ready-made solutions for them.

What do you hope to achieve by being part of 5-HT?

We hope to be connected with more of your partners from the chemical and pharmaceutical industry in order to understand their problems and to determine the measurable output we could achieve by providing an AI solution. The major problem that the industry is facing right now is that corporates already have large amounts of data available which is not utilized for data-driven decision making. This has an immense impact on their profitability. At the moment, Germany is already taking a big leap forward in this regard: the government is putting a lot of effort into promoting artificial intelligence, and shop floor managers are also starting to see the need. But many German companies are still rather slow in making decisions and adopting new technologies when you compare them to US-American and Chinese companies. Perhaps 5-HT can take the initiative and encourage German corporates to start their AI journey. Together, we hope to make one of our visions come true: making Germany the world leader in industrial AI solutions.

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!