How to Improve Manufacturing Processes by Using Human-driven Data

Judith Hillen

“Digitalization on the factory floor will be the norm in a few years,” says Paul Harfas, the co-founder of the startup Octavic, based in Romania and Denmark. His startup provides a monitoring and shopfloor management solution for production processes, enabling a better quality management and maintenance. How can the pharma industry benefit from this system, and why is it important to focus not only on machine data, but also on the knowledge of the people on the production floor? In this interview, Harfas speaks about questions like these and presents the idea of Octavic’s system P.E.T.

Paul Harfas, Co-Founder at Octavic

Paul Harfas, Co-Founder at Octavic Felix Blaga, Co-Founder at Octavic

Felix Blaga, Co-Founder at OctavicHow can your system help to make production processes better?

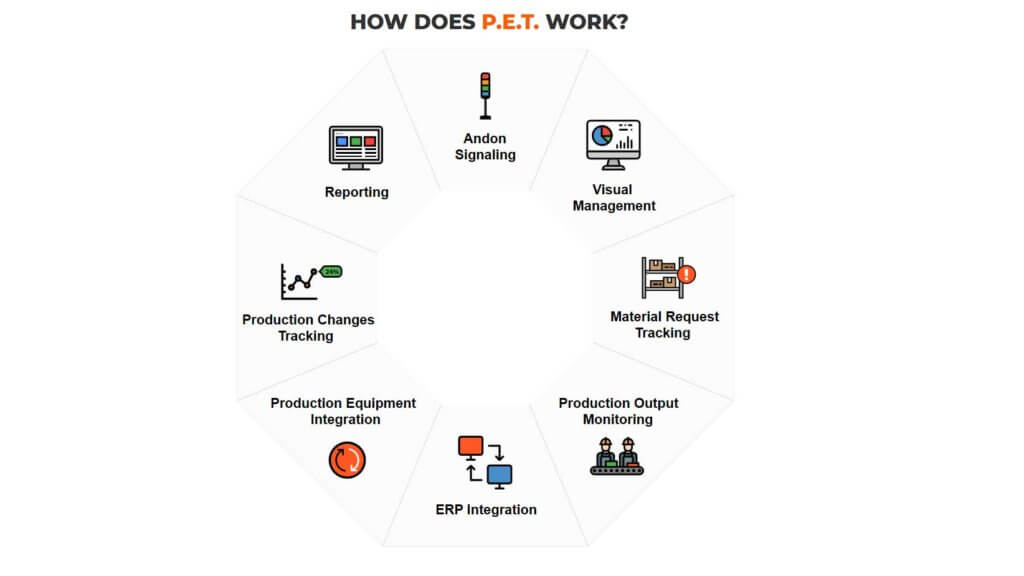

We add value to manufacturing processes by taking data from production lines and enabling manufacturing personnel to contextualize this data in a very user-friendly way. The data can be used in production and quality management and maintenance. By applying advanced machine learning algorithms taking advantage of the context, we facilitate the optimization of production processes. The abbreviation P.E.T. stands for “Production Efficiency Tracker”, but our system has become much more than this: We not only track the efficiency of machines and production lines, but also help improving manufacturing processes.

In which industries can your system be applied?

We started in the automotive industry, but today, we also have a lot of customers working in pharma industry. For example, our system can be used to monitor and manage production lines for medicine. One big benefit especially for pharma companies is that we have validated our system as GMP compliant. By digitalizing part of the required paperwork for batch records, we simplify administrative processes. Regarding new industries, we are planning to expand in different directions – in a first step, we aim to address producers of various agricultural products, in a second step producers of detergents and similar household products. At the moment, our customers are based in Romania, Hungary, Italy, and Denmark, but in general, we are able to cover other European countries, too.

Which aspects can be optimized with P.E.T.?

There are four big topics. First, real-time aspects: We collect real-time information about the production floor, using both machine data and input from machine operators. This information can be presented in many different ways, via smartphone, laptop or large screens, depending on the needs of the different key users. Shift leader, production manager, maintenance manager – they are all interested in different aspects. Therefore, everybody gets the data of interest at the right granularity and in real-time. The second important topic is big data: Based on the data from the production lines, we extract potentials for process optimization. Third, we also use this data to feed it into production scheduling. We take into account both data about the past and about the present performance in order to make real-time adjustments to the production scheduling possible. As a last aspect, we are currently integrating Artificial Intelligence, so we can identify larger patterns of the data and come up with predictive suggestions, for example for predictive maintenance. In the beginning, we started with an analytic system. But we do not only want to deliver business intelligence, we want to close the feedback loop by helping our customers to make use of their data. The first step was our real-time production scheduling engine, the next step is Artificial Intelligence.

What are the problems of existing solutions for managing manufacturing processes?

We have two types of competitors – first the big players with established Enterprise resource planning (ERP) or Manufacturing Execution Systems (MES). However, these systems are quite monolithic, inflexible and inconvenient to use. They do not provide an intuitive interaction between the system and the operator: If the operator wants to input data, he has to leave his workplace and go to a computer. The second group of competitors are other startups. There are many startups offering hardware for data collection, but a lot of them do not focus on the human aspect, on the knowledge of the people on the production floor. As a result, the user simply gets a lot of charts, but no contextualization of the data. What manufacturing companies need in order to drive forth production process optimization, is a mix of data from the production lines and context knowledge of the people working on the production floor.

Compared to that, what are the benefits of your system?

Our system was designed to make it as unobtrusive as possible for the end user and to make it easy for him to add his knowledge to the database. For example, if a machine stops, the operator needs to input the reason for this event. Instead of having to leave his workplace and go to a computer, with our system, he can input the reason with two touches on a touchscreen. Furthermore, the reasons for the stoppage are contextualized: The operator can choose from a list of reasons which are contextualized based on experiences or on the point of the line where the machine stopped. This helps him to input the correct reason into the system. With P.E.T., we want to enable manufacturing companies to make use of the knowledge of their employees. Our system is based on human-driven data: We enrich machine data with human knowledge, and we make it easy to connect these two sources.

How did the idea for your startup develop?

Octavic was founded together with Felix Blaga, my classmate since 5th grade who also went to the same university as me. His background lies in software development, mine in electronic development. During university and afterwards, we gained experience in various manufacturing organisations. Because the city in which we studied was a center for automotive production, we were mainly involved with production processes in the automotive industry, working on quality measurement systems for the industry. Our idea for Octavic evolved over the years. It was put in a drawer and taken out again, until in 2015 we actually started working on our product and our business model, with a piece of paper, drawing diagrams on both sides.

What is your current status of development?

In 2016, after we found our first customer willing to pilot the system, we developed the first version. By testing our system with the first customers, we learned how to improve it and implemented new ideas. At the moment, we are working on further improvements and developments. Besides, we are enlarging our sales team and building our customer support. For installation and customer support, we are looking to expand our network of partners, so we can stay lean and agile as a young company and focus on our core competencies, the development of our product.

What does your vision for the future look like?

We would like to offer manufacturing organisations the equivalent of a control panel in an airplane, with all the indicators and feedback systems, so that they can diagnose and react in real-time and, by that, achieve a better performance. In short, we want to become the industry standard for shopfloor management and process improvement for manufacturing industries. Digitalization on the factory floor will be the norm in a few years. There are a lot of exciting developments going on right now, and we want to push it even further.

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!