Easier access to machine data for software developers and engineers

Judith Hillen

In many manufacturing companies, machines communicate via the Industry 4.0 standard OPC-UA (OPC Unified Architecture). Developers and engineers who are not well versed in this complex data exchange standard have to rely on OPC-UA experts to access machine data in such cases. The startup konektilo from Rosenheim, which is part of the 5-HT network, wants to change that by making machine data accessible via the standard REST interface. In the interview, the two founders Roman Paeske (CEO) and Michael List (CTO) tell us how konektilo works and how this solution enables both frontend developers and engineers to easily build the interfaces they need.

konektilo Team Michael List (B. Eng.), Roman Paeske (MBA & Eng.), Prof. Dr.-Ing. Oliver Kramer, Marc Andrae (MBA & Eng.)

What does konektilo do?

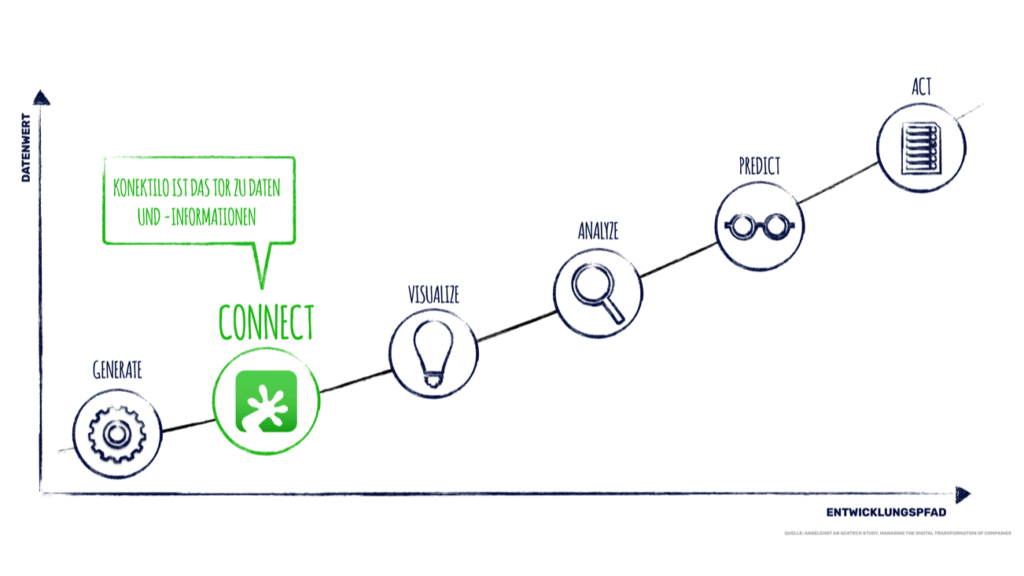

Roman Paeske: konektilo is a software startup that develops REST APIs (REST: Representational State Transfer, API: Application Programming Interface) for OPC-UA. To put it simply: we enable software developers and engineers to easily access machine data without in-depth OPC-UA knowledge in order to be able to process, visualise and analyse it in a meaningful way.

What is the significance of OPC-UA for manufacturing companies?

Michael List: OPC-UA is the Industry 4.0 communication standard that enables data exchange between machines and is becoming more and more widespread in industry. One of the great advantages is that OPC-UA can be used across platforms. In addition, OPC-UA offers various options for reading out machine data or sending data to the machine. The problem, however, is that this communication standard is very complex. For a front-end developer who is not familiar with OPC-UA, it is therefore difficult to get the machine data he needs to develop user-friendly apps and web interfaces. This is where we come in, by translating OPC-UA towards REST. RESTful APIs are a widely used standard on the web, through which, for example, web apps like weather apps get their data. Practically every software developer knows how to work with REST interfaces. So by translating OPC-UA into REST, we make machine data more accessible and usable for software developers.

Who are konektilo's customers?

Roman Paeske: We target manufacturing companies from a wide range of industries. As soon as there are machines with OPC-UA interfaces whose data are to be further processed, we can get started with konektilo. One focus so far has been on mechanical engineering, but chemical and pharmaceutical companies that use OPC-UA can also benefit from konektilo. Within companies, there are two user groups for whom konektilo is relevant: firstly, the front-end developer who needs machine data to build his interfaces, and secondly, the IT-savvy engineer who knows and controls the production processes. We want to make machine data so easily accessible that in the future not only software developers but also engineers will have uncomplicated access to the data they need.

How does the use of konektilo work?

Roman Paeske: konektilo is a plug-and-play product because it is very important to us that our customers can start using it quickly. Within half an hour they can get the first data from their machines. Because konektilo is a Docker container, the end user needs a computer or server on which Docker is installed. He enters the desired machines in the configuration file and can connect to them directly. After that, konektilo provides a standardised REST interface. The user can either make targeted REST calls to request or send specific data, or set up subscriptions to be automatically notified when certain values change.

konektilo connects people, machines and data

What are the main benefits for your customers?

Roman Paeske: With konektilo, companies can do without OPC UA experts, which can be a great advantage because there are very few of them and they are correspondingly expensive. On the other hand, there are many front-end developers who have mastered REST and can work directly with machine data with the help of konektilo without needing long training periods. Furthermore, we build on solid, standardised technologies. REST has been established for years, and OPC-UA has been driven forward for several years by the OPC Foundation, which develops standardisations for various industries, so that in combination a technically clean solution is created. With konektilo, companies can also save the cost of OPC-UA client licences that they would otherwise need to get access to machine data. Overall, we empower software developers and IT-savvy engineers to quickly and easily get the data they need to develop the solutions they need.

Which concrete use cases can be implemented with konektilo?

Roman Paeske: One of our biggest customers is a wood processing company with 70 machines at different locations in Europe. This company was using a Manufacturing Execution System (MES) to manage and monitor the machines, which was very expensive but did not solve the actual problems. We often observe this issue: many companies say that we actually have to build our own solutions for our processes, but for that we need machine data that we can't easily access. That's where we come in with konektilo, by making it easier to access the data. Together with the wood processing company, we have developed a customised interface based on konektilo. This allows us to provide the different user groups, such as management, order planning and maintenance, with the data they need. This interface is now being successively developed further in the company in order to be able to map the processes precisely. konektilo is the gateway to the data here.

How did the foundation of konektilo come about?

Roman Paeske: The idea arose from the proto_lab research project at the Rosenheim University of Applied Sciences, in which we looked at how the furniture production of tomorrow can be designed with the help of IoT. As co-founder, I was responsible for project management; Michael joined us as a software developer.

Michael List: For the development of an application, we needed access to the data of a milling machine. However, we could not easily access this data because the machine communicated with OPC-UA. That's why we asked ourselves: How can we make machine data more easily accessible for developers?

Roman Paeske: We developed the first prototype of konektilo in the proto_lab. Parallel to my work at the university, I also worked as a consultant in industry and saw that many manufacturing companies were struggling with similar problems to ours. Therefore, we quickly realised that our solution was also needed by others. In May of this year, we finally founded konektilo as an independent company. Besides Michael and me, two other software developers and bachelor students are currently working for konektilo.

What are the next goals for konektilo?

Roman Paeske: We are currently working on expanding our distribution network. We are also on the lookout for the next useful features that we could integrate. For example, we have determined that our customers actually need a solution that not only gives them access to the data, but also helps them to build interfaces on this basis. Currently, we solve this problem by realising individual interfaces for our customers in the project business. But it would also be conceivable to integrate a second module in the area of visualisation into konektilo so that, for example, engineers without much IT know-how can also use it to build surfaces.

How can companies find out whether konektilo fits them?

Michael List: We offer a free trial version that can be downloaded from our website. All the features of the full version are already available in the trial version - with the restriction that only one machine can be connected and that a maximum of five variables can be retrieved. This way, companies can find out within 30 minutes, without obligation, whether konektilo works for them.

What do you hope for from the cooperation with 5-HT?

Roman Paeske: First of all, we are excited about the many options that 5-HT offers for startups. For us, this support is very valuable. After all, it is still a challenge to start a company in Germany. 5-HT's network is very exciting for us in terms of potentially building strategic partnerships or getting in touch with potential customers in the chemical and pharmaceutical industry. Therefore, we are very happy to be part of the ecosystem.

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!