Chemicals – A Mature Industry goes digital

Dr. Marko Lange

The chemical industry is the only one which is named after a natural science where it has its roots. No wonder that science played a major role in this industry which is still one of the most R&D intensive ones. And that does not apply only for new products in terms of substances and their application and production processes but also to business administration where chemicals were leading in making use of scientific management approaches setting even management trends.

Despite this great tradition it is fair to say that chemicals were not leading what we call digital transformation. Instead, many in the industry are still trying to find out at what digital transformation might bring to the industry and to which extend the industry will be impacted at all. This is not surprising having in mind that a chemical plant is not so easily replaced by digital means such as platforms like Uber changing the transportations sector or Airbnb impacting the hotel business.

In contrast to chemicals as a mature industry looking back to a history of more than 150 years it is an even older and more traditional industry which is pretty much advanced and ahead when it comes to digitalization of business. And that industry is the agri-business including agrochemicals serving that industry which is reflected by approaches like digital or smart farming or better to say precision farming when it comes to the application of agrochemical products. So, could it be that maturity boosts digitalization and that chemicals as a whole not only agrochemicals will be soon deeply impacted?

Digital disrupters ahead

The maturity of an industry brings commoditization of products and production processes which results in margin erosion since it is increasingly difficult to differentiate from new competitors entering the market. In consequence, chemical companies try to cut costs by automating the back office and running low-touch operations. Digital technologies like the Internet of things, Machine learning and robot process automation can help to achieve that. Next to this cost advantage triggered by digital technologies chemical companies have the option to make use of new technologies to deliver entirely new customer and consumer experience and become more independent from sheer product volume sold. Instead, new business models will incorporate services ranging from simple aftersales service offerings through complex problem-solving co-innovation offerings to even outcome-based business models all including programs to monetize corporate knowledge, intellectual property and data assets.

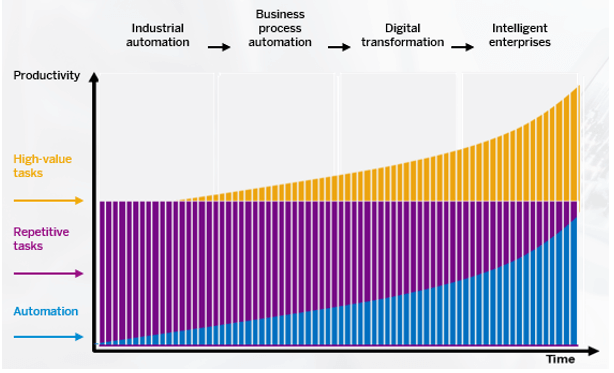

Fig. 1: Digital Technologies such as Machine Learning and Robot process automation can help to automize repetitive tasks to free up resources for higher value tasks saving time and money.

Fig. 1: Digital Technologies such as Machine Learning and Robot process automation can help to automize repetitive tasks to free up resources for higher value tasks saving time and money.

Platform economy

In fact, the driving force behind the latter is not just differentiation from competition beyond products next to cost advantages. It points to the fact that we face 2 main upcoming digital disruptors which are the platform economy and the circular economy. Digitalization raises the expectations of buyers of chemical products regarding the buying experience which should be like what they know from their B2C buying experience. It is not any longer the case that customers might refuse to record a sales order in an e-commerce system insisting of fax, mail or phone as order-entry channel. This allows new startups and trading platforms to get a foot in the door between chemical companies and their industrial buyers of chemical products so that established B2B channels come under pressure. In response, the buying experience need to be superior and bundled with superior service offerings.

Circular economy

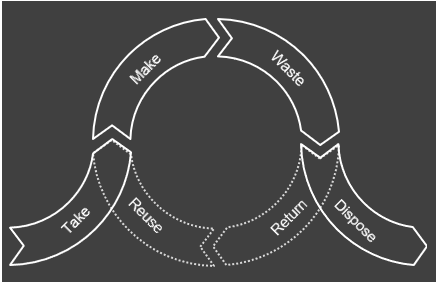

Despite the great achievements regarding emission cuts and material and energy efficiency after decades of the chemical industry´s responsible care initiative, the current discussions around climate change and plastics waste pollution show that there is a lot of pressure on this industry to act becoming part of the solution and not being part of the problem. It is a threat and opportunity at the same time. Chemical solutions help to save energy and produce and use renewable energies and new concepts like power to chem are means to become carbon free. A circular economy looks at the whole life cycle of products being as efficient as possible in all life-cycle phases and trying to avoid as much as possible waste and raw material input. Success in a circular economy without the chemical industry is hard to achieve because of the chemical industry´s material and material processing knowledge. But it would also be a nightmare for the chemical industry if industrial users of chemical products would become independent from chemicals by helping themselves. So, again new business models and services, innovation and collaboration in networks and restructuring of our current linear supply chains are needed and all that is facilitated by new digital technologies.

Fig. 2: Circular economy aims to reduce input and waste. But this means more than just recycling. It impacts all phases of a good manufactured.

Fig. 2: Circular economy aims to reduce input and waste. But this means more than just recycling. It impacts all phases of a good manufactured.

Digital becomes the new norm

Both, cost savings needed because of its maturity and digital disruptors reshape the chemical industry making digital the new norm. And that applies for the whole value chain of a chemical company as the following real examples show which is by far not an exhaustive list.

Smart Labs

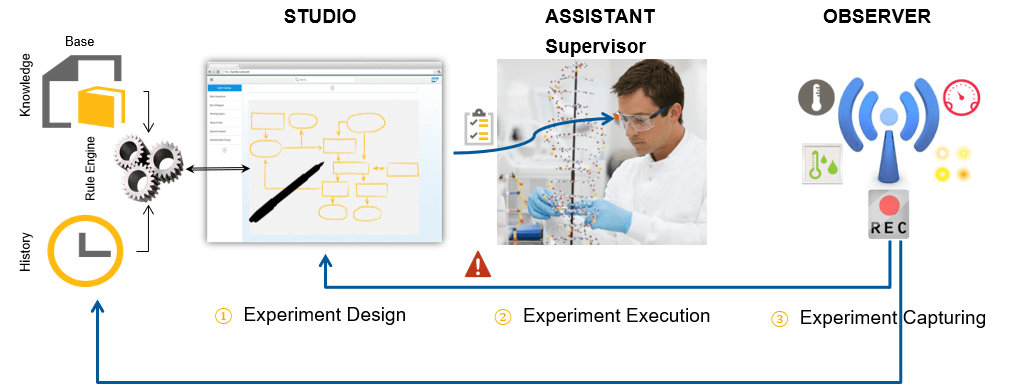

The lab will be a central place talking about digitalization in chemicals. Quantum-computing is a prominent example but pretty much related to basic research. The Internet of Things can help to easier connect lab equipment with information systems if all parties agree on same standards talking about technical protocols and data semantic. Having enough recipe information available and combining that with product attributes allows to find the right recipe for a given technical problem based on predictive analytics and using that information to train machine learning applications can even allow to let an IT system make formulation proposals which are then reviewed and validated by formulators.

Fig. 3: Digitalization of the labs helps to electronically capture trial results and reducing the number of trials by making use of those data enabling digitally assistance of formulation.

Fig. 3: Digitalization of the labs helps to electronically capture trial results and reducing the number of trials by making use of those data enabling digitally assistance of formulation.

Digital Plants

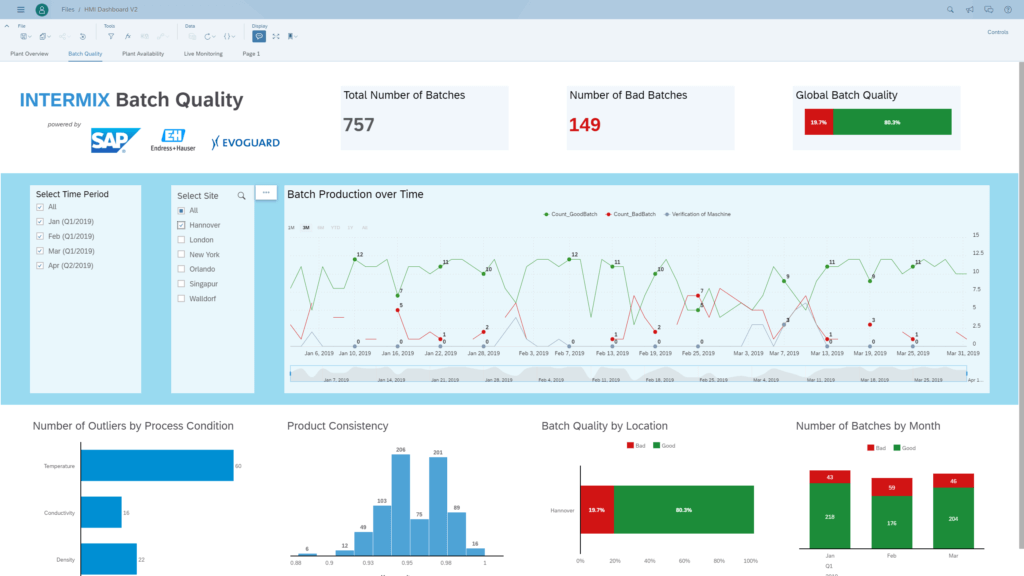

Depending on the instrumentation and automatization of a plant lots of data are gathered already and the Internet of things might help to collect even more data in even more plants. But their use is still limited. Digitalization brings many more capabilities to visualize, process and analyze those data. Specifically, the prediction of mal-functions and quality issues based on sensor data can help to increase safety and uptime of technical assets and to assure quality.

Fig. 4: Analytics of sensor data in the digital plant can have many purposes such as material and energy efficiency and improved asset utilization or - as shown here – the influencing factors of quality.

Fig. 4: Analytics of sensor data in the digital plant can have many purposes such as material and energy efficiency and improved asset utilization or - as shown here – the influencing factors of quality.

Adaptive Logistics

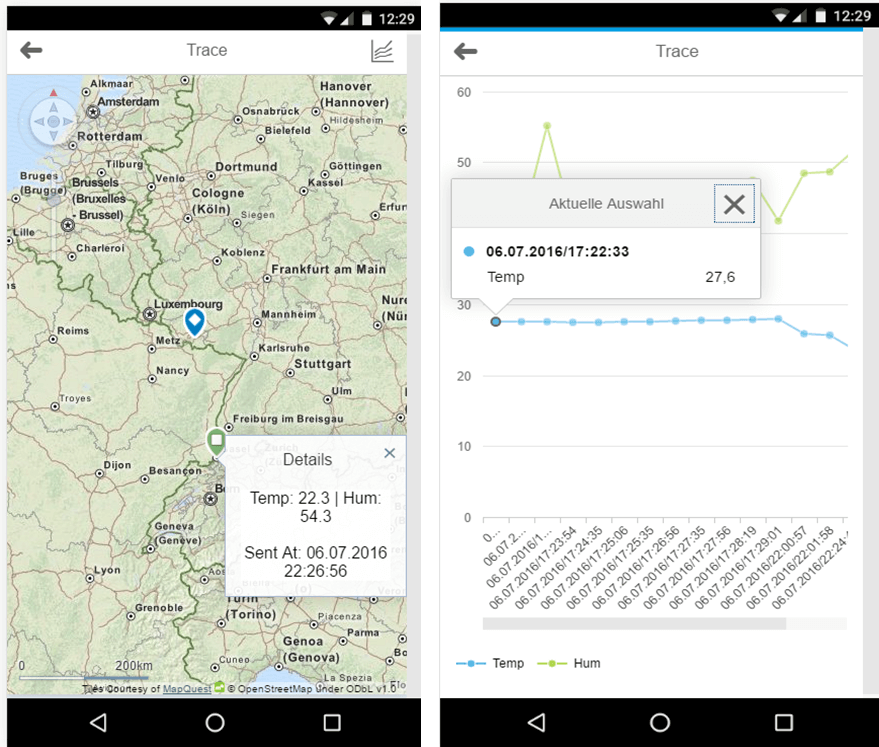

In logistics, digitalization helps to better track goods movements along the transportation chain and to easier collaborate with logistic service providers. That optimizes logistic operations outside the company. Moreover, tracking and tracing ensures product integrity (e.g. cooling chain, prevention of product counterfeits) and in combination with block chain technology it is even possible to proof product origin and ownership in those cases where the proprietor changes while the product is still transported. Finally, tank level monitoring enables replenishment scenarios and returnable and expensive containers can be observed.

Fig. 5: Tracking the location of containers (here gas cylinders) and conditions (here pressure to derive filling level) to optimize replenishment and ensure supply chain integrity.

Fig. 5: Tracking the location of containers (here gas cylinders) and conditions (here pressure to derive filling level) to optimize replenishment and ensure supply chain integrity.

Superior customer experience

Customer interaction is increasingly IT based. It goes far beyond product catalogs and web shops where orders can be placed. Customer portals offer the room for complex interactions including applications that support customers in applying chemicals like a color consultancy platform which helps consumers to select a decorative paint, digital farming apps that provide advice to farmers on field treatments or lab assistants which support formulators on customer side to select the right ingredients. Moreover, open and co-innovation engagements get facilitated covering the gathering of technical requirements, solution finding, sampling and customer feedback.

Agile Enterprise

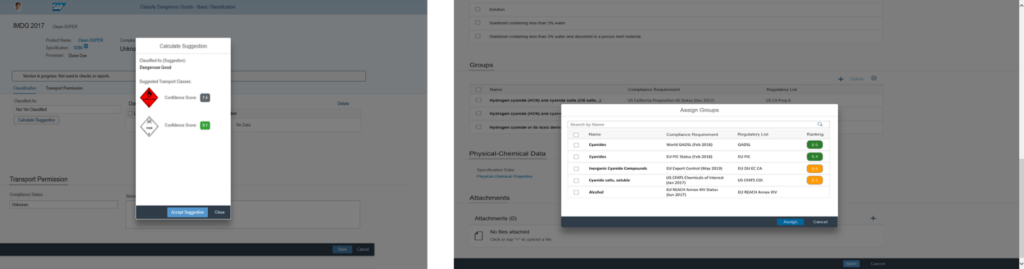

Digital technologies can help to shorten cycle time which results in higher responsiveness and flexibility. This becomes possible since repetitive administrative tasks now can be automated. Examples for this are chat bots for sample and safety data sheet ordering, a digital sales assistant that allows to request customer and product information and to record customer visit reports through conversational UI, robot process automation in many business processes and machine learning. The latter can be used for chemical specific tasks like dangerous goods classification and of course many tasks that are not specific to chemicals like customer request assignments to the right person or department or matching of payments to orders both inbound for accounts payables and outbound for accounts receivables.

Fig. 6: Dangerous Goods Classification and Substance Group Assignment with Machine Learning

Fig. 6: Dangerous Goods Classification and Substance Group Assignment with Machine Learning

Front-office meets the back-office. At the Digital Hub for Chemistry & Health 5-HT?

The above examples all have one in common. They are so to speak front-office or satellite applications for a specific purpose used by a customer, operator, sales or service representative, application technician and now that we have the Internet of Things one could even say used by a machine. But they need to be integrated with the back-office of a company where all comes together. A predictive maintenance app triggers maintenance orders and blocks a production resource in production planning, customer interactions of all kinds result in inquiries like price, product information and availability or sales and service orders that need to be executed and so on. This makes back-office integration a key success factor for new digital solutions and models and requires a mutual understanding of data and business processes. The eco-system of de:hubs with its digital hub for Chemistry & Health 5-HT can be ideal places making the front and back-office meet combining the process and business expertise and technology of successful companies like BASF and SAP with the innovative spirit of startups.

Author: Dr. Marko Lange

About the author: Dr. Marko Lange is solution manager at SAP SE and responsible for solutions for the chemical industry. With industry experience made at Schering and Beiersdorf he joined SAP in 2000 taking over various roles around SAP for chemicals and pharmaceuticals. He studied industrial engineering specializing in chemical technology and wrote a doctoral thesis about managerial accounting in chemicals.

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!