“Asset intelligence is the future of manufacturing Industry”

Judith Hillen

More and more companies are becoming aware of the fact that they need predictive maintenance to prevent downtimes on the shopfloor.

The Indian startup Ecolibrium, which is part of 5-HT’s digital ecosystem, has developed an asset intelligence solution that goes beyond that. “We don’t just look at equipment from a downtime perspective, but we also ensure that all machines are running efficiently,” says co-founder and director Harit Soni.

In this interview, he explains how chemical and pharma companies can become more productive and sustainable by using Ecolibrium’s asset intelligence solution.

Ecolibrium-Team

Ecolibrium-TeamWho is Ecolibrium?

Ecolibrium was founded with the vision to create asset and energy intelligence for factories and buildings. We use IoT and AI to identify when machines and processes are becoming inefficient or unhealthy.

By analyzing early warning signs, we help our customers to shift from reactive to predictive maintenance. At the same time, we enable them to eliminate all the wastages and inefficiencies that exist in the system. Our partners and customers have seen efficiency improvements by up to 15%, and unplanned downtime reduction by up to 40% – not to mention the elimination of thousands of manhours spent in unnecessary scheduled maintenance activities.

As an organization, we are based in India, but we also have operations in South East Asia, Europe and the US. There are 55 people working for Ecolibrium – data scientists as well as domain experts who understand machines and manufacturing facilities. Our company has also been recognized globally. For example, we received the United Nations’ Momentum for Change award, the International Ashden Award for Powering Business, and a Frost & Sullivan award for being an energy management pioneer.

What is the story behind the foundation of Ecolibrium?

Nine years back, me and my brother Chintan decided to start Ecolibrium together. We were both living abroad at that time: Chintan was working for a technology company, and I was a consultant at KPMG. Because we identified the need for having information technology to make machines, factories, buildings, and cities smarter, we decided to go back to India to develop this technology. Soon we had our first customers and deployed our first real-time asset intelligence solutions.

Why do manufacturing companies need asset intelligence?

We believe that asset intelligence is the future of manufacturing industry because it answers four essential questions about the equipment on the shopfloor:

First, is it running efficiently or not?

Second, is there an operational or equipment health issue causing a decrease in efficiency?

Third, is the asset going to fail in the next couple of weeks or months?

Fourth, if it does so, do I only need to repair it or do I need to replace it?

By answering these questions, we enable our customers to prevent downtimes and to ensure energy efficiency.

How does Ecolibrium help to answer these questions?

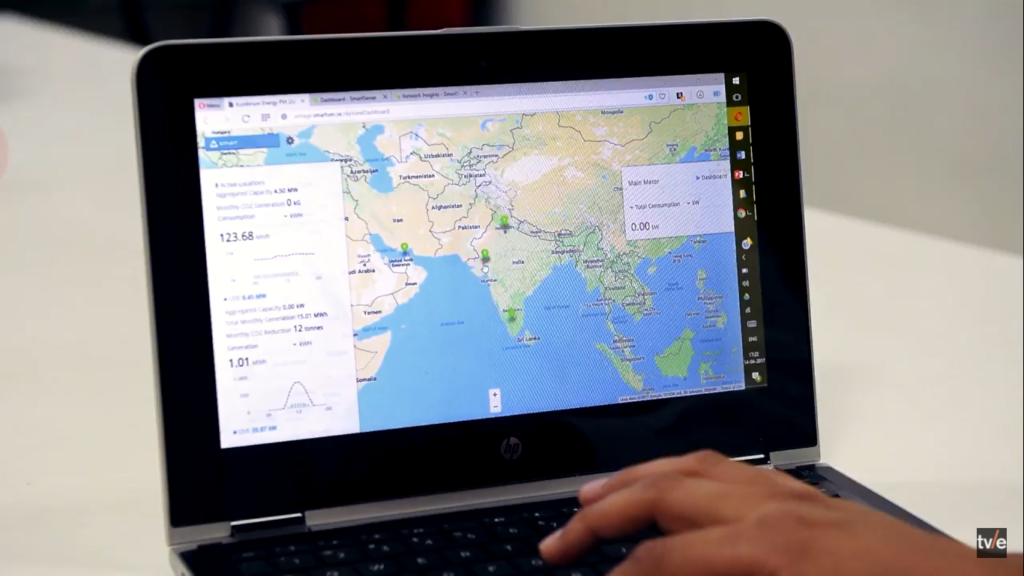

Our flagship product SmartSense is a comprehensive IoT-powered asset and energy intelligence platform including data acquisition capabilities.

First of all, we collect data from the equipment on the shopfloor by deploying wireless sensors and plug-and-play gateways that can easily be integrated into the existing systems. Once we acquired the data, SmartSense analyzes it. Over the last years, we have developed a huge repository of algorithms for a wide variety of equipment, e.g. motors, compressors, chillers, boilers, and transformers. Finally, we provide automated efficiency recommendations and downtime warnings for our users to act on.

There is a lot of competition in the field of predictive maintenance. What sets SmartSense apart from other solutions on the market?

First of all, the breadth of assets that can be monitored with our solution is remarkable. Many companies only focus on rotating machines like compressor, motors, or pumps, whereas we also look at thermodynamic machines.

Second, we provide a full-stack platform. Our customers don’t need to consult another vendor for sensor integration or data transfer. All these aspects are already part of our solution which also integrates with 12 different industry protocols.

Third, we look at assets in a holistic manner. While conventional predictive maintenance solutions only focus on the risk of downtimes, we believe that energy efficiency is also an extremely important issue. This way, we help companies around the world to save energy and become more sustainable.

Our customers in Europe and the US can also take advantage from that fact that our development team is based in India. Due to the lower cost of development, we are able to deliver cutting-edge technology at a very competitive price.

Who are your target industries, and who is already using SmartSense?

We mainly focus on manufacturing industry, especially on pharmaceutical and chemical companies, automotive and engineering companies, as well as food and beverage and consumer good companies.

In these three segments, more than 120 customers in different regions around the world have already deployed our solution, e.g. Intas Pharmaceuticals, Zydus Cadila, and Jubilant Pharma, who is currently using SmartSense to keep its equipment running in order to manufacture materials for a vaccine against COVID-19.

What are the next milestones for Ecolibrium?

Up to now, most of our customers are based in Asia. Now, we focus on working with international partners and bringing our technology to new markets, especially to Germany, the UK, Italy, Spain, and the US. We are looking forward to collaborating with more and more organizations who are looking for an Industry 4.0 roadmap and want to make their machines smarter, more efficient, and more productive. For our operations in Western Europe, we are also going to set up an office in London soon.

How can 5-HT help you to gain a foothold in the German market?

We would love to engage with some of the pharma and chemical companies from your network that we can support on their journey towards asset intelligence.

Furthermore, we are interested in talking to potential strategic partners, e.g. companies providing maintenance services or equipment to pharma and chemical industry who we can form strong collaborations with.

What is your vision for the future of Ecolibrium?

Our vision is to become the leading IoT-powered asset intelligence service companies globally. Since our motto is “Reimagining Tomorrow,” we reimagine the tomorrow of how equipment and factories are managed. With our technology, we want to be able to make any machine on the shopfloor, any factory, and any building as efficient and healthy as possible.

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!