A digital lab for research & development

Katharina Kittelberger

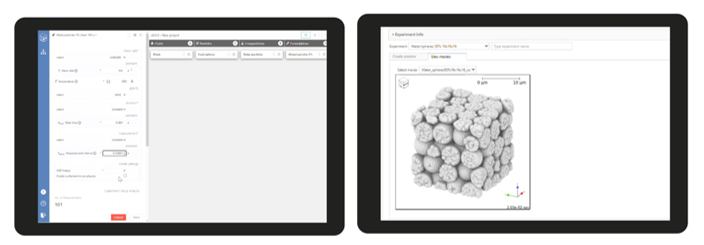

Thanks to RheoCube's digital experimentation software, scientists can drastically reduce the amount of trial-and-error experimentation needed. With its scalable simulation tool, this Dutch scale-up, founded in 2015, offers for the first time a scientifically validated alternative to the costly trial-and-error methods that are primarily used in on-site laboratories.

By moving the analog lab experiment into a digital environment with appropriate lab realities, we can not only create virtual prototypes, but also replace up to 80% of synthesis and lab experiments.

- Jurjen van Rees, MSc.

In an interview with 5-HT, Jurjen provides some insights into the technology behind RheoCube and its many benefits.

What is the intention behind developing this software?

"In any company, research and development must respond quickly to keep pace with changing customer demands and increasing competition," Jurjen begins. "So far, this challenge has been addressed with conventional chemical research and development (R&D). However, this approach has the disadvantage of being very costly and unpredictable from an operational standpoint.

It also cannot keep pace with trends such as the growing need to use sustainable ingredients without sacrificing end product performance.”

For this reason, RheoCube sees enormous potential in digital R&D. With a broad range of computing and modeling skills on its team, the scale-up offers a breakthrough scalable simulation tool for experimental scientists. Previous technical barriers are thus a thing of the past.

A virtual lab: Because new dimensions offer space for new possibilities

A virtual lab: Because new dimensions offer space for new possibilitiesWho is the target audience for your virtual lab?

"In general, our software supports experimental scientists working at organizations that use R&D for their product development. Our customer base starts with companies that have an annual turnover of 50 million euros," says Jurjen. "We target a number of different industries, such as the food and pharmaceutical industries, but companies in the personal care, homecare or coatings sectors can also use our virtual laboratories to take that crucial step towards digitalization.”

Or more accurately, wherever liquids are present in the product, RheoCube has a role to play.

A virtual lab promotes data-driven R&D, enabling companies to improve their decision-making, drive innovation, and ultimately gain a competitive advantage.

The laboratory of tomorrow offers a host of new advantages:

That is, faster findings and lower costs at the same time. Jurjen clarifies, "Suppose a group of scientists still sees discrepancies in their product development after several test runs. RheoCube gives them that flexibility to quickly change a particle shape, size, or chemistry and focus on a particular subset or ingredient in their formulations," he explains. "And they can do it without setting up another experiment."

As a result, problems can be localized more quickly and systematically. In this way, online experiments provide answers directly, so everyone involved can concentrate on the most important thing: getting on with their work. "Over time, these rapid findings also build up a deeper understanding of the various formulations and ingredients, adding to organizational knowledge" adds Jurjen.

From the micro to the macro level - and vice versa

The RheoCube workflow is like that of a physical formulation laboratory. Materials can be designed, which are then subjected to external forces. In addition, various material reactions and transport properties can be measured.

Processes that were previously impossible become possible: Remove gravity or double it in one experiment? No problem.

There are many different elements, which customers can incorporate into their simulations. "This enables RheoCube to answer questions on what the future physical behavior of products will be," Jurjen comments. "In doing so, we can facilitate comprehensive access to the microstructure of materials, such as virtual material prototyping and formulation development. This gives our customers full information about their materials in use and how they behave in certain situations. This can be very difficult to do in physical experiments, depending on what is being studied."

Valuable insights into the microstructure of different products can be used to investigate both the static and dynamic properties of a system, such as stability or rheology. Questions such as, "What is the effect of changing this ingredient?", or "How does that environmental parameter affect a property?", can from now on be answered.

Understanding at such a deep level improves research, which in turn also supports faster product development.

How do your customers use the software?

"In principle, we offer our customers the simulation software as a browser-based system based on a "plug-and-play" principle. This means that anyone can log in quickly and easyly to immediately start virtual lab work," says Jurjen.

After the experiment, customers quickly receive comprehensive data and visualization sheets. Thus, not only can the results be analyzed, but the composition of end products can also be transparently screened. "The latter," Jurjen hints with a wink, "is actually impossible in the lab."

RheoCube offers almost endless possibilities to conduct experiments and discover the nature of their behavior.

Ultimately, RheoCube generates a wealth of relevant data and information on the physical behavior of ingredients and their interaction with other ingredients.

"In doing so, we monetize our concept primarily in two ways:

On the one hand, we charge a basic fee per user for issuing the licenses. Then there is an annual license fee," he explains. In fact, RheoCube simulation software is unique in the world. Jurjen also smiles as he says:

I know it's an ambitious statement, but we have no other competitors in our field.

Because until now, no one has offered such a simulation concept that combines micro- and mesoscale aspects. Equally unique: the computing effort is kept as low as possible for the user. "Although the development of highly detailed simulations requires large parallel computers, or high-performance computing (HPC) resources," Jurjen explains, "we provide these in a cloud and on-demand."

This frees companies from the need to have this computing power at their disposal. Likewise, the computing services used maintain the highest security standards, so all data generated is safe.

How do you plan to expand your success to date and what role does 5-HT play in helping you achieve your goals?

"Currently, about 30% of our customers are in the U.S., others are in Europe, with the majority in Germany. In five years, we plan to gain further market share in the U.S. as well as show initial success in Asia. This is because there are many chemical companies in this region that can benefit from our concept.

As an established player in the market, we set the standard for simulation software.

"We see 5-HT as being truly entrepreneurial, practical and agile. Because Germany is currently the most important market for us in Europe," says Jurjen, "cooperating with 5-HT provides an opportunity to get to know different German companies and strengthen our current base in a very interesting and fast-moving part of the world.”

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!