Thermal protection systems - designed for the extreme

Celine Jörns

How can product designers and engineers create resource- and energy-efficient products while protecting them from extreme conditions? Blueshift's team of thermal specialists offers suitable solutions to solve their customers' difficult thermal problems.

Specifically, Blueshift designs, develops and delivers efficient thermal protection systems (AZ-TPS) based on the startup's AeroZero® polyimide aerogel film technology. In doing so, it pursues a mission to develop more sustainable solutions for aerospace, defense and specialty electronics.

Learn how Blueshift's patented AeroZero® technology works and its potential impact in our interview with the startup’s president Tim Burbey.

Tim Burbey, President of Blueshift

Tim Burbey, President of BlueshiftHow would you explain your solution in three sentences to a professional colleague in a chemical company?

"Blueshift enables product designers and engineers to protect critical structures, components, and electronics so that they can now survive in extremely hot and cold environments. Our patented AeroZero® technology structures air into 3 quadrillion nano pockets per square meter of 165 micron continuous roll to roll film. Leveraging AeroZero, Blueshift makes two distinct product lines:

Multi-functional thermal protection and management systems, which can perform from -200 °C to 2,000 °C, and

Ultra-low loss, ultra-low dielectric substrate materials for electronics."

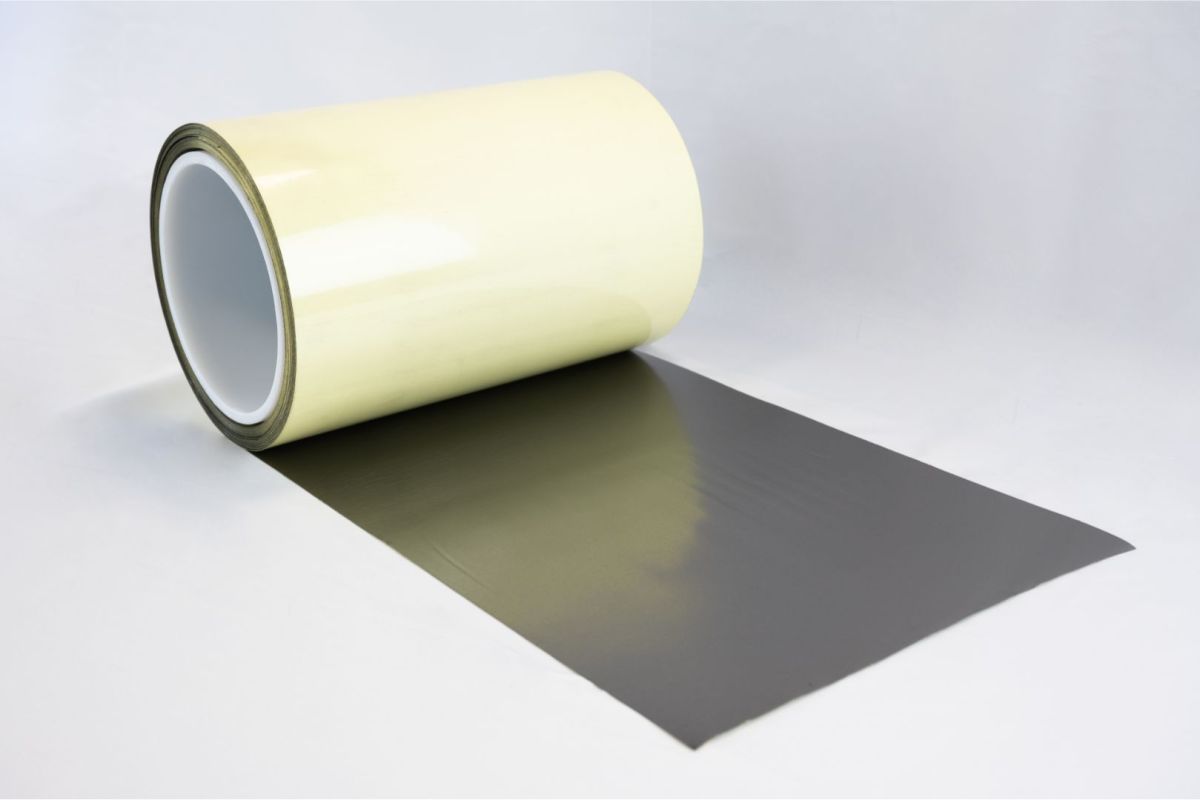

Blueshifts thermal protection system

Blueshifts thermal protection systemWhat problem motivated you to found the company?

"We started Blueshift to help tackle some of the most pressing issues facing product designers: weight, space and temperature. There was an urgent need for lighter weight and lower profile flexible materials that could protect critical structures, components, and electronics so that they could survive in extremely hot and cold environments while driving resource and energy efficiency.

For the electronics materials side of our product line, 5G has driven the need for lower loss high performance materials that can survive much hotter operating temperatures. We thought a high air content structured material would be of value to product designers. We might have been a bit early, but we were right."

How do you convince a chemical company to set up a pilot project with you?

"As in our case, innovation can advance more quickly in a smaller firm focused on higher-risk bleeding edge research versus a larger chemical company with entrenched business focused on lower risk activities.

We are thermal material and structured air specialists working on some of the most challenging designs in the world, directly with leading OEMs. Our disruptive technology enables designers to push innovation in their product configurations making their products more resource and energy efficient. Because of this we have the large OEMs approaching Blueshift for our expertise.

Chemical companies are eager to participate in many of these product areas, e.g., making lithium-ion battery systems safer for aircraft; designing higher performing carbon fiber systems for hydrogen fuel; lowering the dielectric constant and loss tangent in products. So, we are approached by chemical companies to see if there are ways for us to collaborate in these high growth opportunities.

Pilot project areas that we are interested in exploring include broadening the chemistry beyond our polyimide base and developing our powder format, which could be, for example, compounded into the partners resin systems. There are several opportunities for new products extensions."

Who are your current customer (groups) and who do you want your potential customers to be?

"We serve customers in the Aerospace, Defense and Specialty Electronics markets within North America and Western Europe. Within all 3 segments we make multi-layer functional products for environmental “protection”, “safety” and “efficiency” of:

Lightweight Structures (carbon fiber, plastic, metal)

Electronics (including Energy, Batteries)

5G & RF Infrastructure

For example we are selling to rocket manufacturers, airplane manufacturers, defense contractors, battery companies, printed circuit board players and a host of designers needing to protect lightweight structures and electronics within their products configurations."

Rocketape powered by Blueshift

Rocketape powered by BlueshiftWhere do you see yourself in 3 years and how can 5-HT support you?

"In the next 3 years, our product line will grow substantially as new programs currently in beta testing with customers will enter manufacturing and become available to wider markets. Additionally, we are planning on manufacturing in the UK via our existing UK subsidiary and potentially the EU to better serve our global customers. 5-HT can support us by continuing to grow the ecosystem in Europe for companies like Blueshift and to connect us with relevant partners customers that we can support."

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!