Anything In, Anything Out: Digging companies’ data gold mine

Ronja Schrimpf

An already proven and validated technology. An open platform which can take any data in and put any analysed data out. A software which allows to see and use all your data, whether it is IT, OT, IoT or any other form of data such as files or PIDs. This is dDriven, a dataDriven startup which developed a platform called UNLSH (pronounced unleash) to exploit a company’s data. In an interview with 5-HT, CEO Partha Ray from dDriven’s Singapore Team and Sugato Ray from dDriven’s India Team are telling what’s behind their startup’s platform, which is already being used by several Manufacturing giants in Asia and now might conquer the European and German market.

What’s behind your name dDriven?

“We pursue excellence in the area of data driven technology. We offer our customers a platform to exploit their data in the best way possible. This is why we called our startup dDriven, which is short for data driven.”

What’s behind your idea of exploiting company’s data?

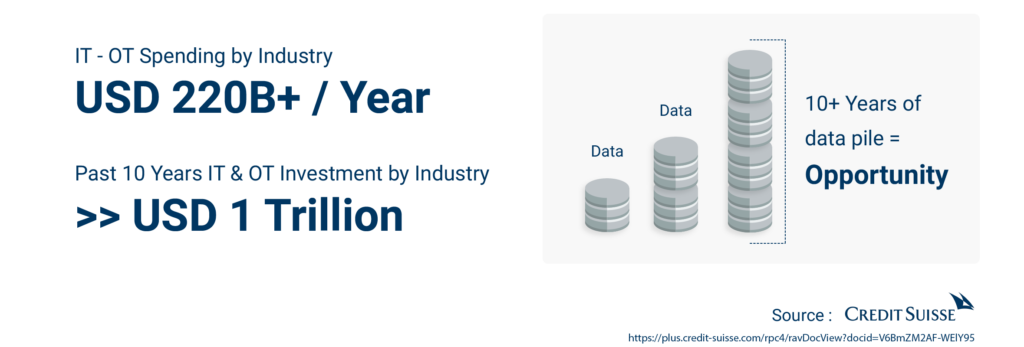

“The manufacturing industry has invested approximately 200 Billion US Dollar per year on IT (information technology) and OT (operational Technology) systems over the last 10 years. These systems are core to manufacturing but are siloed and essentially have a trillion-dollar goldmine of data locked in them. With the advent of IoT, the data-pile is also increasing day by data. Leveraging this data holistically is an extremely difficult task. Most of the Digital Transformation work being done today is merely adding a layer of disparate analytics on top of the disparate data. This is the core challenge we are addressing. Our platform, UNLSH, solves this problem of Disconnected Manufacturing by leveraging all IT, OT and IoT data.

This is a study that talks about the large investments going into IT & OT systems from manufacturers. You can directly have a look here: https://plus.credit-suisse.com/rpc4/ravDocView?docid=V6BmZM2AF-WElY95

The industry is also starting to wake up to what this data is worth. Over the last couple of years, several industry giants, many of which are our customers now, have reached out to us asking “We want to Digitalize, how do we leverage our IT and OT data?” Until now, there was no foundational data platform or tool to exploit business and manufacturing operations data very easily because of the technical difficulties around blending all of this data in a way which allows for holistic analytics. And this is where dDriven comes into play. We are solving this problem.”

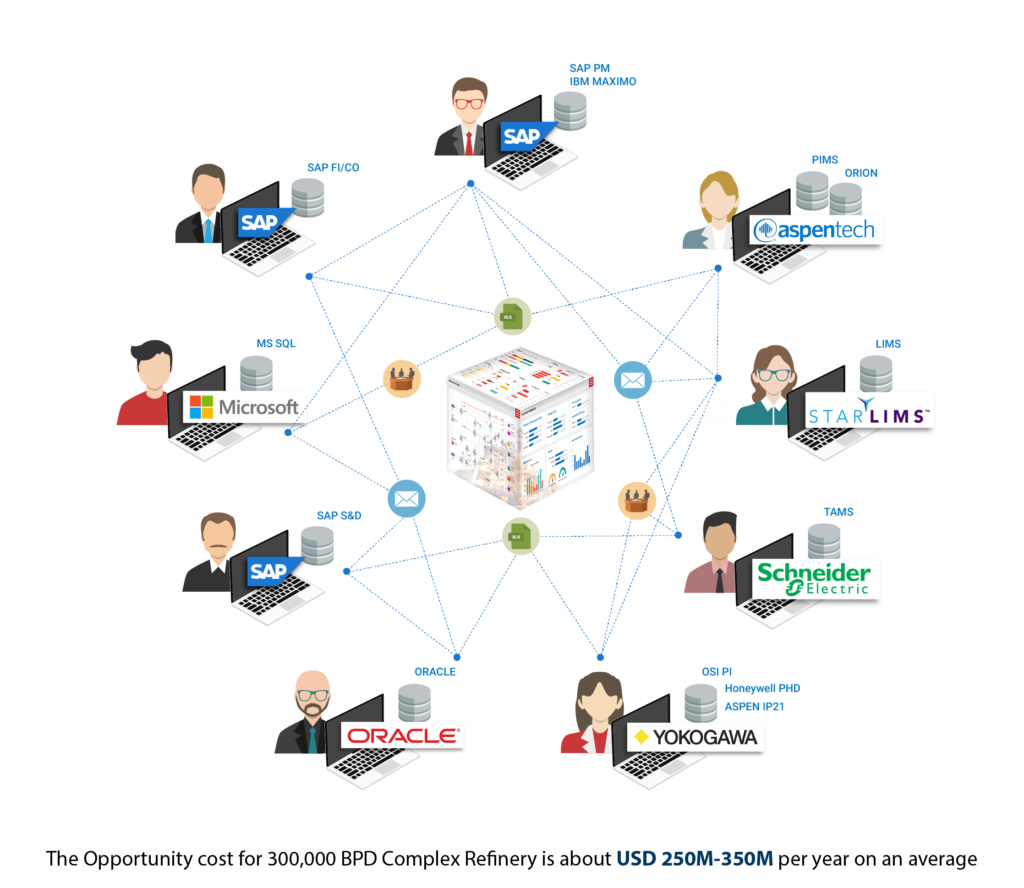

This image shows all the IT & OT systems a massive amount of data remains locked. It also highlights the problem of converging all of this data together to deliver contextualised insights (these are also some of the systems UNLSH ingests data from)

This image shows all the IT & OT systems a massive amount of data remains locked. It also highlights the problem of converging all of this data together to deliver contextualised insights (these are also some of the systems UNLSH ingests data from)What’s behind your platform that differs you from other startups?

“The first difference between us and other startups in this area of analysing data are that we for once are developing a platform any engineer can use with simple steps as ‘drag and drop’. This means for exploiting the data from your system, you don’t need any specialised IT experience or knowledge and you don’t need to code. This drastically reduces your “Time-to-Value”. Today, a Digital Transformation project of just 1 single plant takes about 2 years, and that too without any flexibility or prospect of scaling. With dDriven’s UNLSH, however, you can do it within 14 weeks and scale rapidly as and when needed.

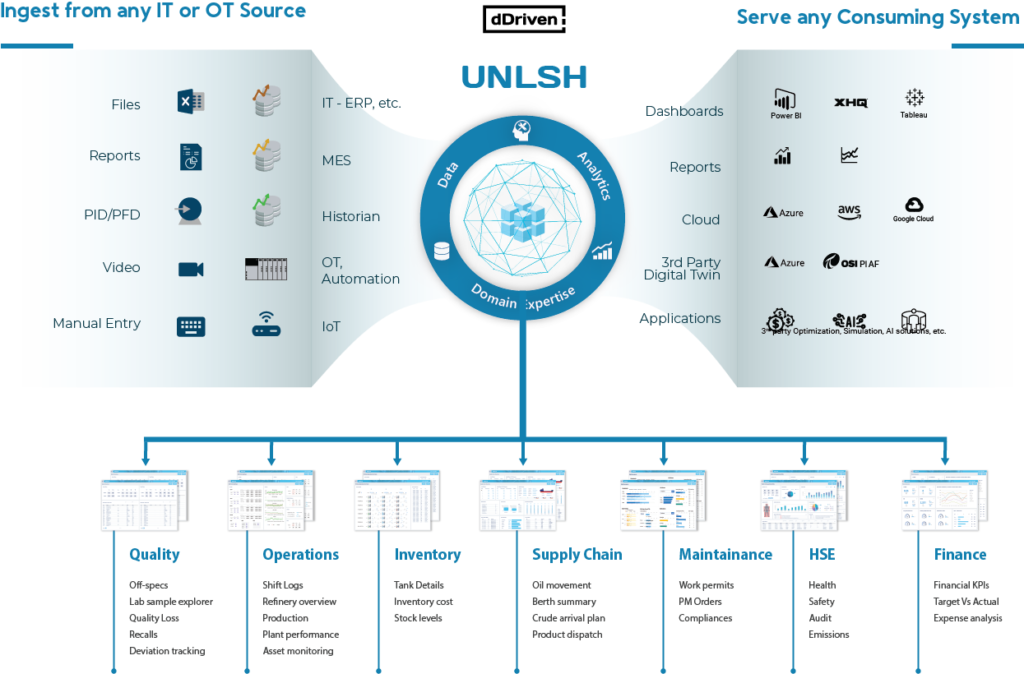

The second difference between us and other startups is that we have an open platform. It is agnostic to any system, whether it’s SAP or Siemens or anything else. It can ingest from any system, and serve any system. For example, you can serve your IT and OT data or analytics to a cloud such as Microsoft Azure, to any Machine Learning Workbench of your choice, or any visualisation tool of your choice. That is why our platform works under the principle ‘Anything in, anything out’.

Overview image of UNLSH showing all of the systems in connects to rapidly expedites digital transformation for manufacturers

A third and very important difference is UNLSH’s Operations Digital Twin. Data Modelling is core to any form of analysis when it comes to industrial data. Doing this through classical IT data modelling is extremely slow and does not allow for flexibility or scaling as industrial data in spread across many systems. However, UNLSH allows users to use a simple drag-and-drop interface to rapidly model any entity using it Operations Digital Twin workbench. These entities can be physical ones such as equipment or non-physical ones such as work processes and functions. Therefore, the Operations Digital Twin essentially becomes a Real-Time Cyber Replica of the entire enterprise. It is a core part of our platform.”

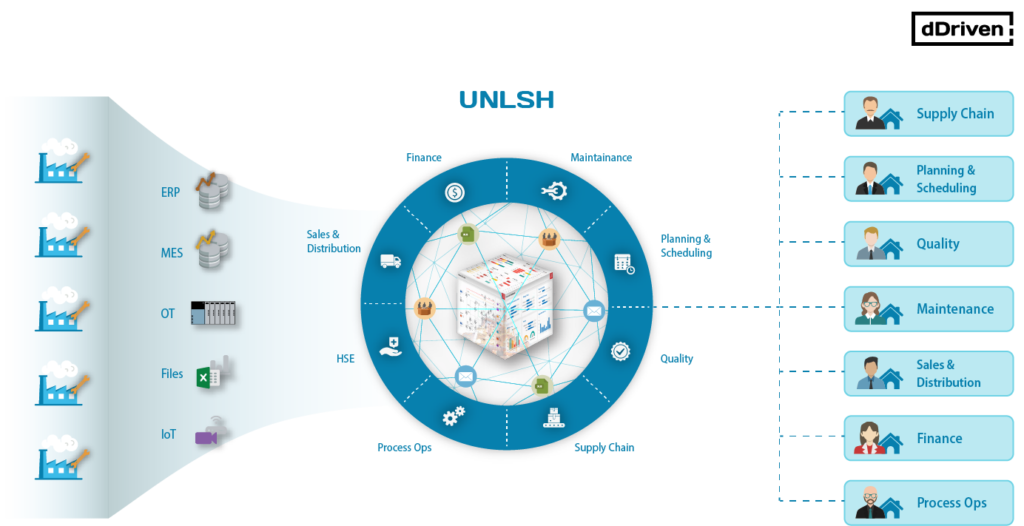

This shows how UNLSH contextualises data and delivers contextualised insights and foresight to key stakeholders and also enables remote operations

Who’s behind your startup?

“We started as a small team in 2016, with three formal founders and two founders who joined later. Today, we are 25 people at dDriven. We have a team in Singapore, where I am located, and one in India, were Sugato is located. We also have partners in Japan and in the USA.”

What’s behind your business plans?

“Right now, we are mostly focusing on the process industry as a whole and in particular on the hydrocarbon and chemical industries. We have established our product in the Asian market already. We want to move to a more mature market now, which is why we want to start with the German market. Because of its industry and its reputation, making it in the German market means being proven globally. In the end, we want to move to the European market, so Germany is a good way to start.

To add to that, given the maturity of the German industry, decisions are made quicker there when compared to Asia. We have always found the decision-making process in Germany to be quite straight-forward and that is very helpful as it brings about clarity in terms of sales.

We have a decent understanding of how the German market is, we understand its industrial customers and their problems, and are confident that our technology would add a lot of value there. However, lack that industry contacts required to showcase our proven platform in Germany. This is where we need help from 5-HT. Right now, we are looking for partners, customers and investors. This is why we are part of 5-HT.”

What’s behind your network’s experience?

“We entered 5-HT’s network through the German Accelerator Program in Singapore. We started with an introduction session with 5-HT and right now, just got passed the introduction stage. The first initial stage about how 5-HT can help us out and connect us with the German chemical industry, however, was very good.

Of course, we wish for more contacts in the industry. But we also want to raise awareness about the importance of data and analytics.

What’s behind your future vision?

“This is a very difficult, but also a very exciting journey. We want to make dDriven’s platform a very successful product – technically, it is already very good, but it has to be used by a few thousand customers, first. But thankfully, we are an already proven platform and working with Fortune 500 customers on large-scale deployments. We have highly validated ourselves, so we have good chances to prove ourselves in the European and German market, too.”

5-HT Chemistry & Health Newsletter

Want the latest tech and industry news, events, relevant info from the ecosystem and more?

Subscribe to 5-HT Newsletter now Subscribe to 5-HT Newsletter now

Become part of the 5-HT Chemistry & Health

Exchange ideas with innovative startups and future-oriented companies in our ecosystem. We look forward to meeting you!